Safety Tests

Performance Verification

31

Electrical Leakage

The following tests verify the electrical leakage of the monitor:

n

Earth Leakage Current (A3 only)

n

Enclosure Leakage Current

n

Patient Leakage Current

n

Patient Source Current, with Mains Voltage on the Applied Part

Perform all leakage tests any time the unit is opened.

Earth Leakage Current

(A3 only)

This test is in compliance with IEC 601-1 (Earth Leakage Current). In

locations where mains voltage is 100-120 volts, the applied voltage is 132

volts. In locations where mains voltage is 220-240 volts, the applied voltage is

264 volts. The applied AC frequency should be the same as the local mains

(50 or 60 Hz).

All measurements shall be made with the power switch in both

ON

and

OFF

positions.

1. Connect the monitor AC plug to the electrical safety analyzer as recommended

by the analyzer operating instructions.

2. Perform test as recommended by analyzer operating instructions.

Earth leakage current is measured under various conditions of the AC mains

and protective earth conductor. For each condition, the measured leakage

current must not exceed that indicated below

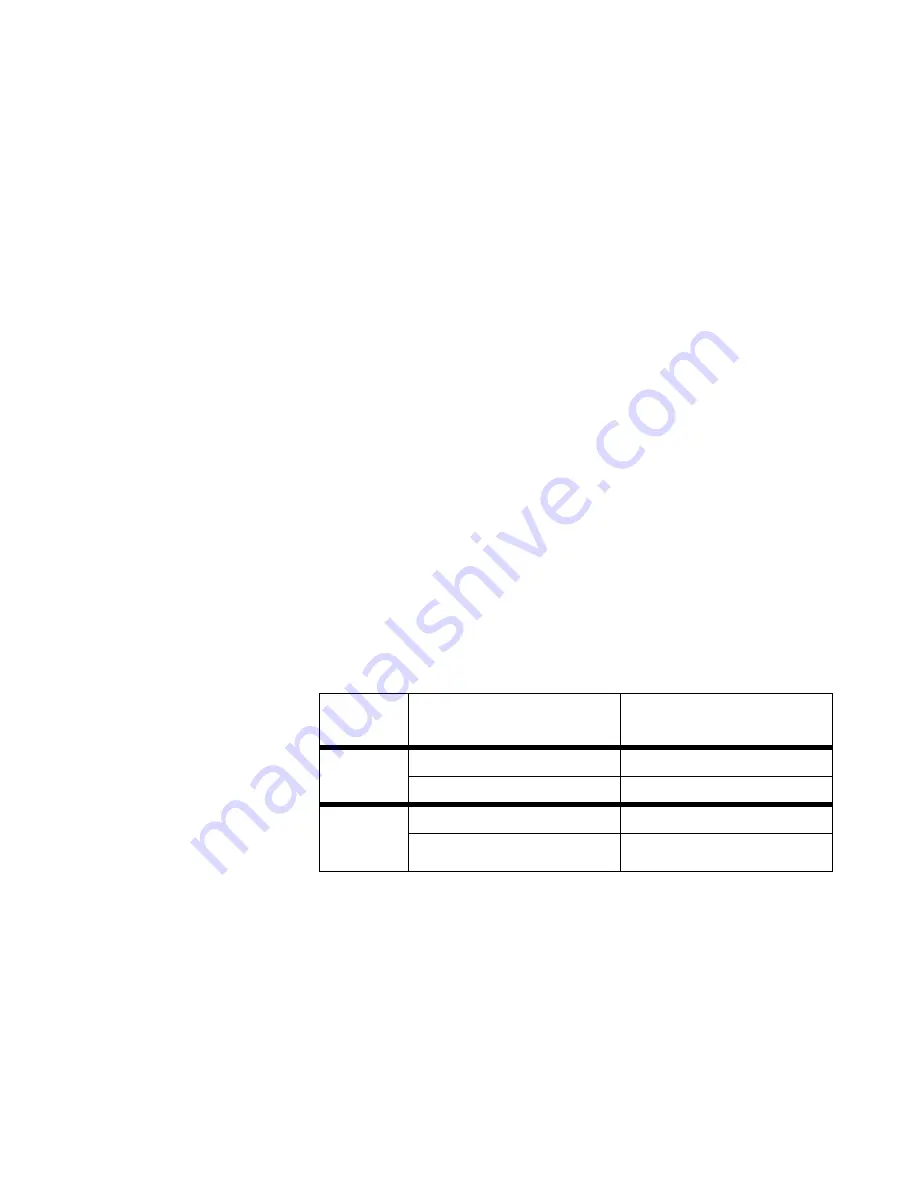

Table 7

Earth Leakage Current Values (A3 Only).

Enclosure Leakage

Current

This test is compliance with EN60601-1 (Enclosure Leakage Current). Test at

110% of the nominal line voltage.

1. Connect the A3’s AC mains power cord to the analyzer as recommended by the

analyzer operating instructions.

2. Using the appropriate test cable, connect the analyzer to the snap nearest to the

handle fixing screw as shown in the following photograph.

Test

Condition

Polarity

Allowable Leakage Current

Normal

Normal

300 µA

Reversed

300 µA

S.F.C

1

Open

Supply

1. S.F.C = Single Fault Condition

Normal

1000 µA

Reversed

1000 µA

Содержание M3921A

Страница 12: ...xii Contents ...

Страница 16: ...Related Documents 4 Introduction ...

Страница 48: ...Safety Tests 36 Performance Verification ...

Страница 72: ...Troubleshooting Guide 60 Chapter 5 Troubleshooting ...

Страница 99: ...Disassembly Procedures A3 Chapter 6 Disassembly Guide 87 NiBP pump assembly Main PCB Main ribbon cable ...

Страница 100: ...Disassembly Procedures A3 88 Chapter 6 Disassembly Guide ...

Страница 102: ...Top Level Assembly 90 Chapter 7 Spare Parts Top Level Assembly Figure 1 A1 Top Level Assembly Drawing 1 of 2 ...

Страница 103: ...Top Level Assembly Chapter 7 Spare Parts 91 Figure 2 A1 Top Level Assembly Drawing 2 of 2 ...

Страница 105: ...Top Level Assembly Chapter 7 Spare Parts 93 Figure 3 A3 Top Level Assembly Drawing ...

Страница 107: ...Front Case Assembly Chapter 7 Spare Parts 95 Front Case Assembly Figure 4 A1 Front Case Assembly Drawing 1 of 3 ...

Страница 108: ...Front Case Assembly 96 Chapter 7 Spare Parts Figure 5 A1 Front Case Assembly Drawing 2 of 3 ...

Страница 110: ...Front Case Assembly 98 Chapter 7 Spare Parts Figure 7 A3 Front Case Assembly Drawing 1 of 2 ...

Страница 111: ...Front Case Assembly Chapter 7 Spare Parts 99 Figure 8 A3 Front Case Assembly Drawing 2 of 2 ...

Страница 114: ...Rear Case Assembly 102 Chapter 7 Spare Parts Figure 9 A3 Rear Case Assembly Drawing 1 of 3 ...

Страница 115: ...Rear Case Assembly Chapter 7 Spare Parts 103 Figure 10 A3 Rear Case Assembly Drawing 2 of 3 ...

Страница 116: ...Rear Case Assembly 104 Chapter 7 Spare Parts Figure 11 A3 Rear Case Assembly Drawing 3 of 3 ...

Страница 124: ...Repacking In A Different Carton 112 Chapter 8 Packing For Shipment ...

Страница 132: ...Theory of Operation and System Architecture 120 Chapter 10 Training Program Block Diagram A1 Figure 1 A1 Block Diagram ...

Страница 144: ...Preventative Maintenance 132 Chapter 10 Training Program ...

Страница 150: ......