a good earth connection to the PAC, which can be accomplished by attaching the DIN rail to a suitable

Earth ground and also utilizing Pin-3 on the Controller DC power input connector. This connection must

be made with the shortest possible, heavy gage wire or braided cable. Low-resistance (<0.5 ohms)

continuity should be verified with an ohmmeter for proper grounding. In addition, all communication

cables should be shielded and grounded, preferably only on one end.

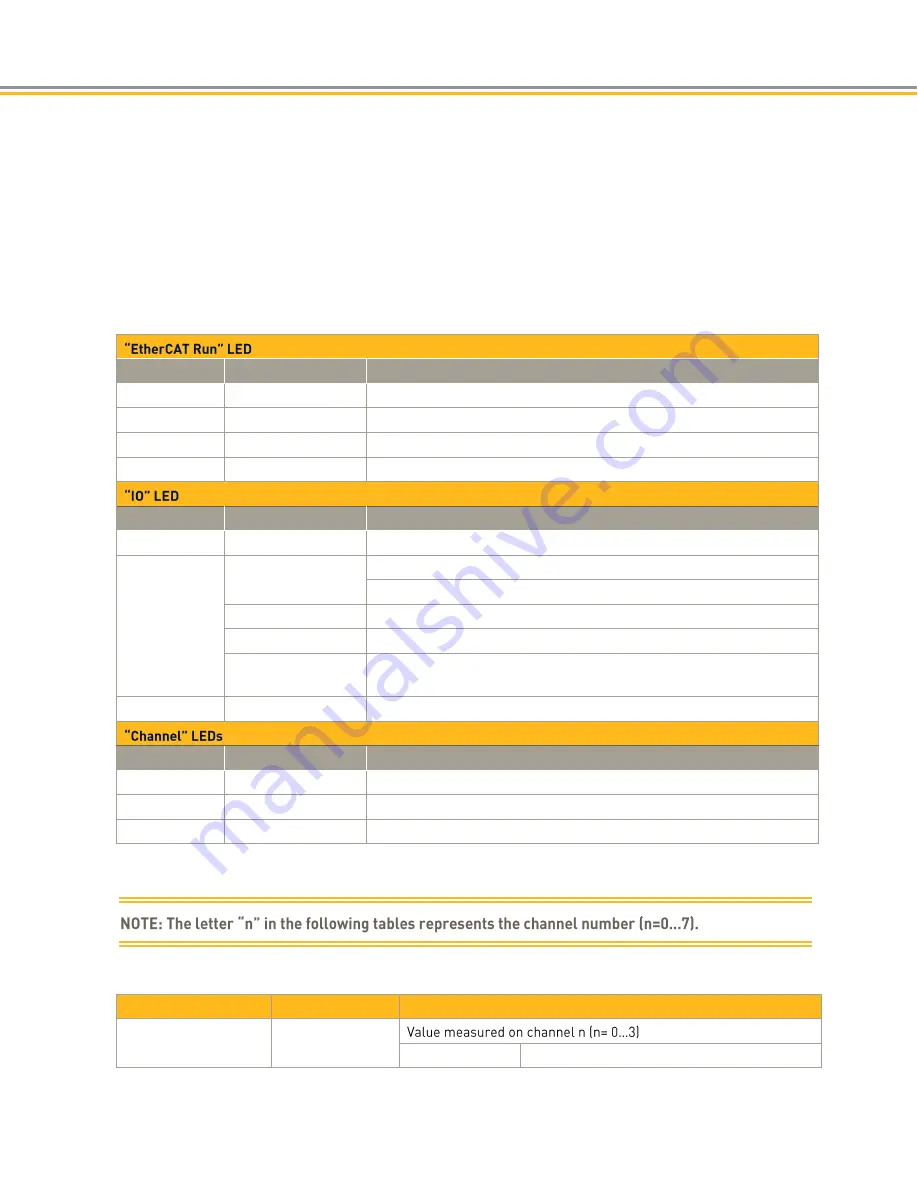

Status LEDs

The LED labeled "EtherCAT" indicates the state of the EtherCAT ASIC. The LED labeled "IO" indicates the

state of the Module inputs and outputs.

State

LED Flash Code

Explanation

Init

Red, on

Initializing, no data exchange

Pre-Op

Red/green, 1:1

Pre-operational, no data exchange

Safe-Op

Red/green, 5:1

Safe operation, inputs readable

Op

Green, on

Operational, unrestricted data exchange

State

LED Flash Code

Explanation

Ok

Green, on

No error

Error

Off

Malfunction of Module if E-Bus LED = On

Inoperative if E-bus LED = Off

Red, 4x

EtherCAT watchdog control

Red, 6x

Module-specific fault

Red, 7x

Configuration error (E-Bus pre-operational), number of process data

differs from that in the Module

Defective

Red, on

Module defective

State

LED Flash Code

Explanation

On

Green, on

Channel enabled

Off

Off

Channel disabled

Error

Red

Short circuit, Broken wire

Analog Inputs

Check the following variable for the digitized input values.

Variable

Data type

Explanation

Channel_n

INT

Default

in 1/10 °C

Содержание PAC

Страница 11: ...CHAPTER 1 Product Overview...

Страница 18: ......

Страница 19: ...CHAPTER 2 Installation...

Страница 33: ...CHAPTER 3 System Start up and Configuration...

Страница 69: ...CHAPTER 4 PACIO Modules...

Страница 143: ...2 After adding the device and code to the project you will configure the IO map as displayed...

Страница 155: ...PAC with 400XR series...

Страница 156: ...PACIO MODULES 156 Parker Automation Controller Installation Guide...

Страница 157: ...PAC with 400LXR...

Страница 158: ...PACIO MODULES 158 Parker Automation Controller Installation Guide PAC with SMH sensors...

Страница 159: ...CHAPTER 5 Communication Interfaces Optional...

Страница 176: ......

Страница 177: ...CHAPTER 6 Troubleshooting...

Страница 188: ...TROUBLESHOOTING 188 Parker Automation Controller Installation Guide...

Страница 189: ...APPENDIX A PAC System Specifications...

Страница 195: ...APPENDIX B Additional Information...