Chapter 1. Installation

2 7

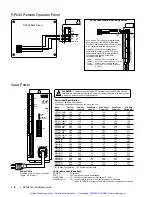

Step 2

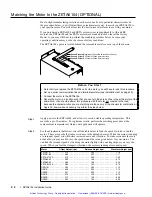

Establish appropriate inductance and static torque settings.

If you ordered a

ZETA6104 and a ZETA motor together as a ÒsystemÓ, these settings were made at the factory

(OS and RS motors may not be ordered as a ÒsystemÓ). Use the

DMTIND

command to set the

inductance, and use the

DMTSTT

command to set the static torque (see table below). The

DMTIND

and

DMTSTT

values are automatically saved in battery-backed RAM.

Motor

--- INDUCTANCE ---

Range

DMTIND

MH

Setting

--- STATIC TORQUE ---

Range

DMTSTT

N-m

Oz-in

Setting

ZETA57-51(S)

20.08 & greater

DMTIND1

*

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

ZETA57-51(P)

5.03 Ð 10.30

DMTIND3

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

ZETA57-83(S)

20.08 & greater

DMTIND1

*

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

ZETA57-83(P)

5.03 Ð 10.30

DMTIND3

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

ZETA57-102(S)

20.08 & greater

DMTIND1

*

0.73 Ð 1.41

101 Ð 200

DMTSTT2

ZETA57-102(P)

5.03 Ð 10.30

DMTIND3

0.73 Ð 1.41

101 Ð 200

DMTSTT2

ZETA83-62(S)

10.31 Ð 20.07

DMTIND2

0.73 Ð 1.41

101 Ð 200

DMTSTT2

ZETA83-62(P)

less than 5.02

DMTIND4

0.73 Ð 1.41

101 Ð 200

DMTSTT2

ZETA83-93(S)

10.31 Ð 20.07

DMTIND2

1.42 Ð 2.33

201 Ð 330

DMTSTT3

ZETA83-93(P)

less than 5.02

DMTIND4

1.42 Ð 2.33

201 Ð 330

DMTSTT3

ZETA83-135(S)

10.31 Ð 20.07

DMTIND2

2.34 Ð 3.48

331 Ð 492

DMTSTT4

ZETA83-135(P)

less than 5.02

DMTIND4

1.42 Ð 2.33

201 Ð 330

DMTSTT2

OS2HB(S)

5.03 Ð 10.30

DMTIND3

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

OS2HB(P)

less than 5.02

DMTIND4

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

OS21B(S)

10.31 Ð 20.07

DMTIND2

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

OS21B(P)

less than 5.02

DMTIND4

0.26 Ð 0.72

36 Ð 100

DMTSTT1

*

OS22B(S)

10.31 Ð 20.07

DMTIND2

0.73 Ð 1.41

101 Ð 200

DMTSTT2

OS22B(P)

less than 5.02

DMTIND4

0.73 Ð 1.41

101 Ð 200

DMTSTT2

RS31B(S)

10.31 Ð 20.07

DMTIND2

0.73 Ð 1.41

101 Ð 200

DMTSTT2

RS31B(P)

less than 5.02

DMTIND4

0.73 Ð 1.41

101 Ð 200

DMTSTT2

RS32B(S)

10.31 Ð 20.07

DMTIND2

1.42 Ð 2.33

201 Ð 330

DMTSTT3

RS32B(P)

less than 5.02

DMTIND4

1.42 Ð 2.33

201 Ð 330

DMTSTT3

RS33B(S)

5.03 Ð 10.30

DMTIND3

2.34 Ð 3.48

331 Ð 492

DMTSTT4

RS33B(P)

less than 5.02

DMTIND4

2.34 Ð 3.48

331 Ð 492

DMTSTT4

(S) = Series Connection; (P) = Parallel Connection

* = Factory default setting (unless you ordered the ZETA6104 with a ZETA motor as a ÒsystemÓ).

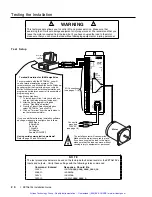

Step 3

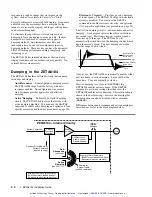

Calculate only the maximum Active Damping (

D A C T D P

) setting.

C A U T I O N

The purpose of this step is to identify the maximum

DACTDP

value for your system

Ð

DO NOT

enter the

DACTDP

command now

. In steps 5-7 of this procedure, never set the

DACTDP

value

higher than this maximum setting.

To calculate the maximum

DACTDP

value, first calculate your systemÕs

total

inertia (include

the motorÕs rotor inertiaÑsee table on page 3). Then consult the table of inertia ranges below

to find the

DACTDP

setting that corresponds to your systemÕs total inertia. If you are on the

boundary between two settings, pick the lower of the two numbers.

DACTDP

Setting

Total Inertia kg-cm

2

Total Inertia kg-m

2

x 10

-6

Total Inertia oz-in

2

DACTDP15

0.088

to

0.205

8.8

to

20.5

0.481

to

1.121

DACTDP14

0.205

to

0.572

20.5

to

57.2

1.121

to

3.144

DACTDP13

0.572

to

1.069

57.2

to

106.9

3.127

to

5.845

DACTDP12

1.069

to

1.754

106.9

to

175.4

5.845

to

9.590

DACTDP11

1.754

to

2.727

175.4

to

272.7

9.590

to

14.910

DACTDP1¯

2.727

to

3.715

272.7

to

371.5

14.910

to

20.312

DACTDP9

3.715

to

5.020

371.5

to

502.0

20.312

to

27.447

DACTDP8

5.020

to

6.275

502.0

to

627.5

27.447

to

34.308

DACTDP7

6.275

to

8.045

627.5

to

804.5

34.308

to

43.986

DACTDP6

8.045

to

9.595

804.5

to

959.5

43.986

to

52.460

DACTDP5

9.595

to

11.760

959.5

to

1176.0

52.460

to

64.297

DACTDP4

11.760

to

14.250

1176.0

to

1425.0

64.297

to

77.884

DACTDP3

14.250

to

15.900

1425.0

to

1590.0

77.884

to

86.905

DACTDP2

15.900

to

17.770

1590.0

to

1777.0

86.905

to

97.129

DACTDP1

17.770

to

20.570

1777.0

to

2057.0

97.129

to 112.465

DACTDP¯

Active Damping Disabled (factory default)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Содержание Compumotor ZETA6104

Страница 45: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 49: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 53: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 63: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...