ENGLISH –

9

Close

Open

SbS

Stop

Bluebus

1 2 3 4 5 6 7 8 9 10 11 12

L1

L2

S

12

LEDs

“L1”

and

“L2”

on the control unit (“

Figure

”) emit some

slow flashes to signal that the learning stage must be carried

out.

To do this:

1.

simultaneously press and hold the

f

and

g

buttons

2.

release the buttons when LEDs

“L1”

and

“L2”

start

flashing quickly (after roughly 3 seconds)

3.

wait a few seconds until the control unit has completed the

device learning phase

4.

once this phase terminates, the

“Stop”

(

S

) LED must be lit

and LEDs

“L1”

and

“L2”

must switch off (LEDs “L3” and

“L4” could start flashing).

4.7 MOTOR SELECTOR

The control unit is equipped with a selector (

A

- “

Figure

”) that

allows for specifying which type of motor to use (see “

Close

Open

SbS

Stop

Bluebus

1 2 3 4 5 6 7 8 9 10 11 12

A

13

m

The motor selector must be set before activating

the mechanical stop learning function.

m

Any configuration not appearing in “Table 4” is not

allowed.

Table 4

SELECTING THE MOTOR TYPE

Motor type

Motor selector

Visualisation on

Oview

T05624I -

TTN3724RHS -

TTN6024RHS

1

O

N

2 3 4 5 6 7 8 9 10 11 12

TO5624I

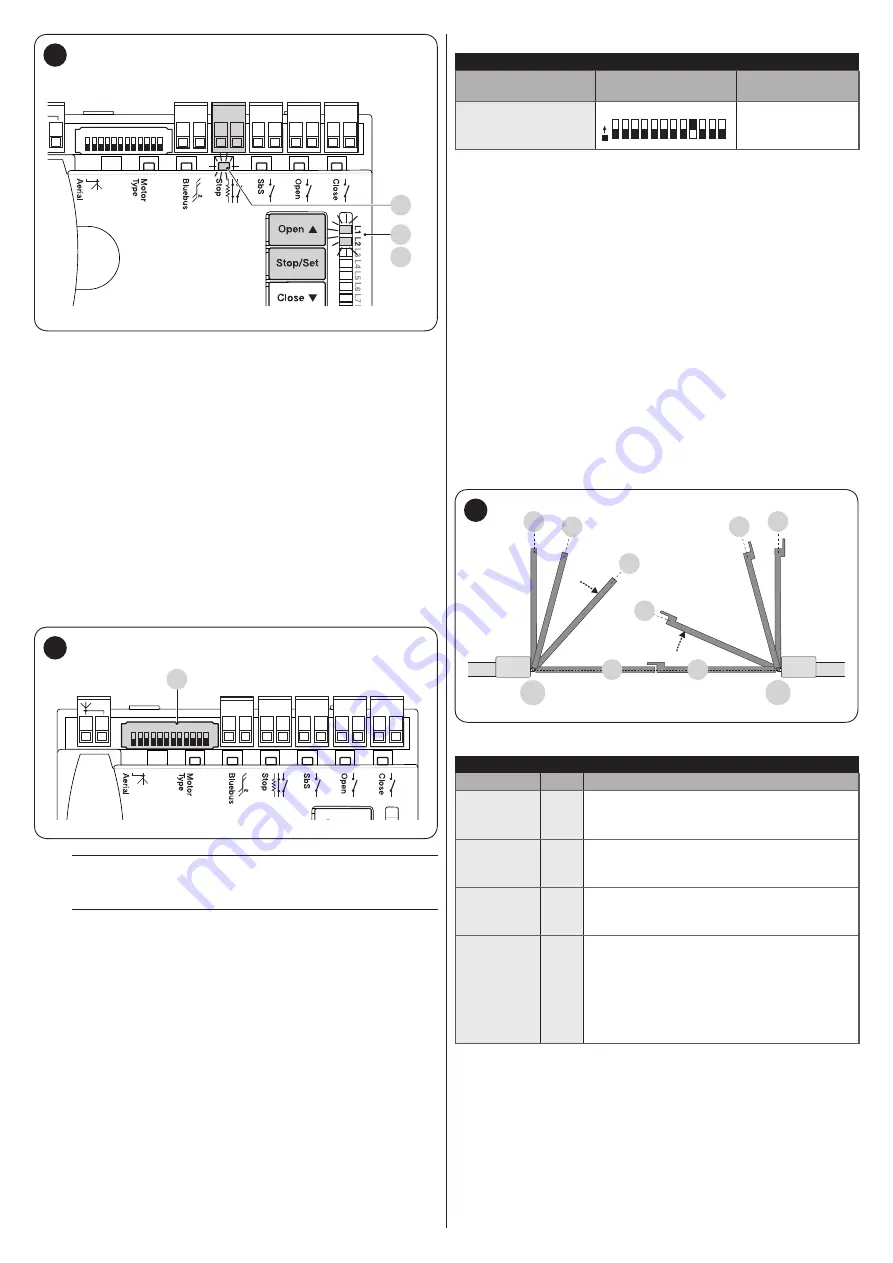

4.8 LEARNING OF THE MECHANICAL STOP

POSITIONS

Once the connected devices have been learned, the mechanical

stop positions must be learned (maximum opening and

maximum closing). This procedure can be carried out in three

different ways:

automatic

,

manual

and

mixed

.

In

automatic

mode, the control unit learns the mechanical stops,

calculates the most appropriate gate leaf offsets and calculates

the slowdown points

“SA”

and

“SC”

(“

Figure

In the

manual

mode, the positions (“

Figure

”) are programmed

one by one, by shifting the leaves to the desired points. The

position to be programmed can be identified when one of the

eight LEDs

“L1...L8”

flashes (see “

“).

In the

mixed

mode, it is possible to perform the automatic

procedure and then, with the manual procedure, modify one or

more positions with the exception of the

“0”

and

“1”

positions,

which correspond to the mechanical stop positions.

1

1

M1

M2

0

0

SC

SA

A

A

14

Table 5

PROGRAMMING POSITIONS

Position

LED

Description

Position 0

(motor 1)

L1

maximum closing position: when the leaf

relative to motor 1 strikes the closing

mechanical stop

Position 0

(motor 2)

L2

maximum closing position: when the leaf

relative to motor 2 strikes the closing

mechanical stop

Position SA

(motor 2)

L3

Offset on opening: when the leaf associated

with motor 2 moves beyond this position,

leaf 1 will start to open

Position A

(motor 1)

L4

Desired opening position: position in which

the leaf associated with motor 1 must stop

at the end of an opening manoeuvre. This

position must not necessarily correspond

to the opening mechanical stop; it can be

chosen as desired between positions “0”

and “1”

Содержание MC824HR

Страница 1: ...Nice MC824HR Control unit EN Instructions and warnings for installation and use...

Страница 24: ...24 ENGLISH NOTES...

Страница 26: ...26 ENGLISH NOTES...

Страница 27: ...ENGLISH 27 NOTES...

Страница 28: ...www niceforyou com Nice SpA Via Callalta 1 31046 Oderzo TV Italy info niceforyou com IDV0133A01EN_15 01 2019...