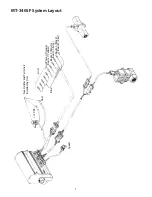

“T” Fitting

Servo

Valve

Relief

Solenoid

16

Illustration 11

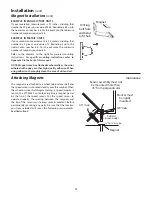

Boom Shut-off Valves

Plumb boom valves with flow-through port as shown. Boom

valves of differing designs may require a “T” fitting. Make

certain to use adequately sized plumbing lines to avoid

ex ces sive pressure drops. DO NOT install the shut-off valves

closer than 12” to the flowmeter.

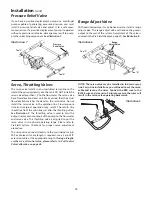

Locate the boom shut-off harness. The boom wires are color-

coded. (If valves have wires, crimp terminals on those wires.)

Attach the cables to the terminals on the boom valves.

Attach a ground terminal to each valve. If valves operate

backwards, reverse connections. Apply silicone grease to the

ter mi nal connections to help prevent corrosion and insure a

good electrical con nec tion.

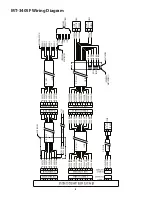

IMPORTANT NOTE: See complete wiring diagram on page 8.

NOTE: To configure your system using motorized ball

valves, see Appendix B.

RELIEF SOLENOID

Illustration 10

The relief valve is used to “dump” pressure when your boom

valves are turned off. Whenever all the boom control switches

are turned off, or when HOLD is selected with the master

switch, the relief valve should be open. Use this plumbing

illustration

(See Illustration 10)

as your pattern for proper

installation if your relief valve has a flow-through port.

DO

NOT

install the relief valve closer than 12” to the flowmeter.

With the relief valve installed, locate the violet wire (tied

back on flow/servo cable) and crimp a female terminal on

the violet wire and connect to relief valve terminal. Connect

other terminal on relief valve to ground.

If your relief valve does not have flow-through port, you must

add a “T” fitting.

See Illustration 11.

NOTE: To as sure a good con nec tion and avoid corrosion,

coat electrical connections with sil i cone grease.

Installation

(cont)

Relief Valve

Care and Maintenance of your MT-3405 F

CONSOLE

Store the console in a cool dry location if it will not be

used for an extended period of time, such as during the

off-season.

As with any electronic equipment, use care in cleaning

so that water or other liquids do not enter the case.

Thoroughly rinse Flowmeter with clean water, install

plastic shipping plugs and keep from freezing.

PRECAUTIONS

•

The input pressure on the glass-filled nylon

flowmeter FM750 GFN should not exceed 100 PSI

(689 kpa).

•

Do not expose the flowmeter to liquid temperatures

exceeding 130 degrees F (55 degrees C).

•

Some chemicals may damage the PPS turbine or

the nylon body of the flowmeter. If you are in

doubt, contact the chemical manufacturer.

Содержание MT-3405 LR F

Страница 1: ...MT 3405 F LR AUTOMATIC RATE CONTROLLER REFERENCE MANUAL TM ...

Страница 33: ...33 Appendices ...