12

EXAMPLE IN ENGLISH/TURF UNITS

If your revolution measurement is 97 inches, dividing that

number by 20 gives you a value of 4.85. Rounding 4.85 up to

the nearest even number is 6. For this example, the minimum

number of magnets required is 6.

EXAMPLE IN METRIC UNITS

If your revolution measurement is 2.5 meters, dividing that

number by .5 gives you a value of 5. Rounding 5 up to the

nearest even number is 6. For this example, the minimum

number of magnets required is 6.

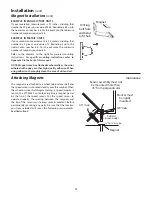

Refer to the diagram to the right for general mounting

instructions.

For specific mounting instructions, refer to

Appendix A in the back of this manual.

NOTE: Magnets may be attached mechanically as shown or

adhered with epoxy or other high quality adhesive. When

using adhesive, thoroughly clean the area of dirt and oil.

Attaching Magnets

The magnets are attached to a wheel hub or drive shaft and

the speed sensor is mounted directly over the magnet. When

the wheel or drive shaft begins turning, a speed impulse is

sent to the MT-3405 F console every time a magnet passes

by the tip of the speed sensor. For the speed sensor to

operate properly, the spacing between the magnets and

the tip of the sensor must always remain constant. Before

permanently mounting any parts, be sure that the location

you have selected will meet the following requirements.

See Illustration 4.

Illustration 4

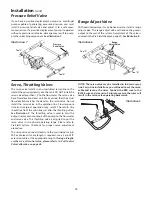

Installation

(cont)

Magnet Installation

(cont)

Drill lug

bolt hole

and bend

to fit hub

Magnet

45° max

Sensor

(Green body)

Magnet

3/8” nuts

Bracket must

be rigidly

mounted

Sensor assembly must not

be mounted more than

45° from perpendicular

¼” to ½” air gap

Содержание MT-3405 LR F

Страница 1: ...MT 3405 F LR AUTOMATIC RATE CONTROLLER REFERENCE MANUAL TM ...

Страница 33: ...33 Appendices ...