ProCon HT 150 / HT 225

2. Installation

2 I n b etri e b n ahm e

2.1

Choosing installation location

The boiler can be operated dependent or independent of the

room air.

The construction allows the boiler to be installed on any load-

bearing surface.

The boiler room must be dry and frost-free. Do not

contaminate combustion air through homogenous

hydrocarbon (e.g. in solvents, glues, paints

[spray cans]), sulphurous compounds (oil chimney) or through

excessive dust accumulation as this may cause burner

malfunction or corrosion damage.

Due to the low surface temperatures, the gas-condensing boiler

and air/flue gas piping system do not need to be placed at a

distance away from combustible parts.

Use the following minimum clearances for connections and necessary setting and

maintenance works:

•

Mounting the boiler

Mount the boiler in such a way that a heater specialist can connect

the lines at the back of the appliance.

The boiler must be mounted securely and in a horizontal position.

Check it again with a level. If necessary, adjust boiler using

adjustable feet.

The boiler has an integrated siphon:

If any construction work is taking place during the installation of the condensing

boiler that may create heavy formation of dust, the boiler should be protected

against dirt with plastic sheet or the like.

The dimensions specified refers to the basic dimension and do

not include the required minimum clearance of 3% (3cm per meter

of horizontal connection line) from the flue gas system to the

boiler.

2.2

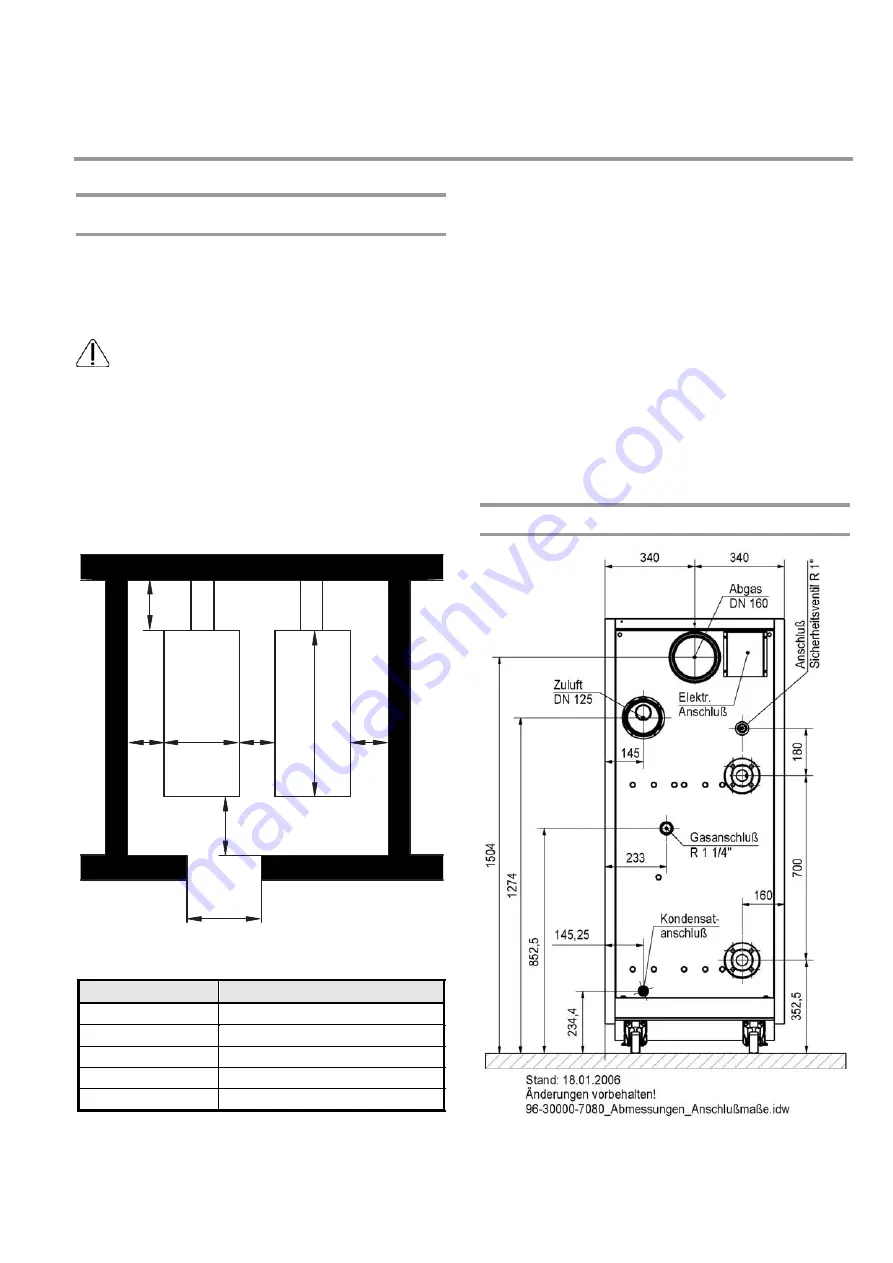

ProCon HT connections

D

A

A A

C

Fig. 2:

Boiler room

Minimum room height: 1800 mm

Dimension

[Dimension in mm]

A 500

B 1000

C 700

D 680

E 1050

Table 1 Mounting dimensions

Fig. 3:

ProCon HT connections

9

Содержание ProCon HT 150

Страница 1: ...1...

Страница 29: ......

Страница 62: ...7 Technical documentation ProCon HT 150 HT 225 7 9 Measurements and connection dimensions Fig 32 62...

Страница 74: ...Notes ProCon HT 150 HT 225 74...

Страница 75: ...HT 150 HT 225 GWB 75 Notes 75...

Страница 76: ...76...