Track Brake

The track brake is normally applied and is hydraulically released to allow

the tracks to rotate.

If the track motor and hydraulic hoses are replaced, the track brake line

must be bled.

On the HMI, navigate to the Chassis Settings screen. Press the Parking

Brake button to disengage the parking brake.

Loosen the track brake hose fitting (smallest hose) until fluid is expelled.

Tighten track brake fitting.

Enable the parking brake on the HMI.

TX04974-04-11-16

9 - 5

Maintenance

Track Tension

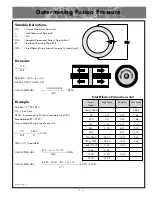

Correct track tension is important to wear of the tracks. If the

tracks are too tight or too loose, it will wear rapidly.

To check track tension:

Place a straight edge across both track idlers. Measure the

amount of sag from the straight edge to the track. Correct track

tension is approximately 1.25" (32mm).

Due to the track on the HMI side of the machine being covered

with a guard, the correct track measurement from the power

pack side track can be used to set the HMI side track.

Measure the distance from the track weldment to the bottom of

the track and use that distance to set the tension of the HMI side

track.

To adjust track tension:

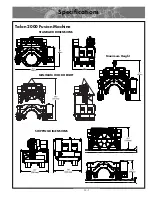

Remove track adjustment cover.

Use a grease gun and add grease to the track grease zerk to

increase track tension.

To relieve track tension, turn the cartridge fitting enough to allow

grease to exit. Removing the grease zerk will not allow grease

to exit.

TX04973-04-11-16

Track Too Loose

Track Too Tight

Track Correct

Track

Adjustment

Cover

Grease Zerk

Cartridge Fitting

Measure Sag

Distance from Track

Weldment to Bottom

of Track

CD0

159

1-0

4-1

1-1

6

CD0

158

9-0

4-1

1-1

6

CD0

1588-0

4-1

1-1

6

CD0

159

3-0

4-1

1-1

6

CD0

159

2-0

4-1

1-1

6

Track Brake Hose Port