# 45466K003

Page 18

Thermostat

Install a room thermostat according to the instructions

furnished with it. Select a location on an inside wall that is

not subject to drafts, direct sunshine, or other heat

sources. The initial heat anticipator setting should be equal

to the total current draw of the control circuit.

Low voltage thermostat connections are to be made to the

blower control board as indicated on the wiring diagram.

Humidifier

Terminals are provided on the blower control board for

connection to a 120-volt humidifier. The

“

HUM

”

terminal is

energized whenever the thermostat calls for heat. Refer to

furnace wiring diagram for specific connection information.

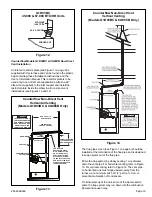

Continuous Low Speed Blower

If continuous blower operation on low speed is desired,

connect the lowest speed motor tap to the

“

CONT

”

terminal on the blower control board (refer to the furnace

wiring diagram.) The blower will operate on low speed

whenever main power is connected to the furnace, except

when it operates on heating or cooling speed during

thermostat call for heat or cooling.

This constant air

terminal is intended for low speed only.

If a motor is

wired for a higher speed, the increased amp draw could

cause the board control to fail and void the warranty.

Electronic Air Cleaner

Terminals are provided on the blower control board for

connection of a 120-volt electronic air cleaner. The

“

EAC

”

terminal is energized whenever the thermostat is calling

for heat, cooling, or continuous blower. Refer to the

furnace wiring diagram for specific connection information.

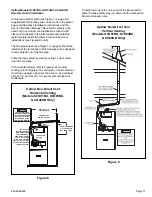

Twinning

The blower control board is designed to permit

“

twinning

”

of furnaces (two furnaces connected to a common supply

and return air system, and controlled by one thermostat).

An accessory kit must be ordered from the manufacturer.

Specific wiring and operating instructions are included

with the kit.

Each furnace must have its own dedicated vent system.

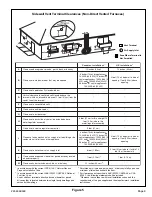

Table 3

Minimum Filter Requirements

1. The Airflow Descriptor is the two digits following

the

“

D

”

in the model number.

2. Areas and dimensions shown for cleanable filters

are based on filters rated at 600 feet per minute

face velocity.

3. Typical filter sizes are shown; however, any

combination of filters whose area equals or

exceeds the minimum area shown is satisfactory.

w

o

l

f

r

i

A

r

o

t

p

i

r

c

s

e

D

s

r

e

t

l

i

F

e

l

b

a

s

o

p

s

i

D

s

r

e

t

l

i

F

e

l

b

a

n

a

e

l

C

a

e

r

A

.

n

i

M

)

.

n

i

.

q

s

(

e

z

i

S

)

.

n

i

(

.

y

t

Q

a

e

r

A

.

n

i

M

.

n

i

.

q

s

(

)

e

z

i

S

)

.

n

i

(

.

y

t

Q

9

0

0

8

4

5

2

x

0

2

1

0

4

2

0

2

x

6

1

1

0

1

0

8

4

5

2

x

0

2

1

0

4

2

0

2

x

6

1

1

2

1

6

7

5

0

2

x

6

1

2

8

8

2

0

2

x

6

1

1

4

1

2

7

6

0

2

x

0

2

2

6

3

3

0

2

x

0

2

1

6

1

8

6

7

0

2

x

0

2

2

4

8

3

0

2

x

0

2

1

0

2

0

6

9

5

2

x

0

2

2

0

8

4

5

2

x

0

2

1