# 45466K003

Page 12

Counterflow Models G1D93BC & CG90CB Direct Vent

Installation

An inlet air restrictor plate (see Figure 1 on page 5) is supplied

with this furnace and can be found in the plastic bag containing

these Installation Instructions and the User

’

s Information

Manual.

This restrictor plate is to be used only in non-direct

vent applications.

See the non-direct venting sections on

pages 11 and 13 for more information on installing the restrictor

plate in non-direct vent applications.

The flue pipe screen (see Figure 1 on page 5) should be

installed at the termination of the flue pipe and is designed

to keep objects out of the flue pipe. An additional screen

should

not

be placed in the intake termination. If a screen is

installed, the air intake may freeze shut.

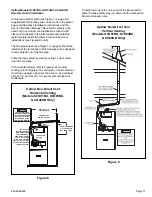

Prime the trap system by slowly pouring 1 cup of water

down the vent pipe. For horizontal venting, refer to Figure 10.

For vertical venting, refer to Figure 11. The vent pipe on

horizontal runs must slope upward, away from the fur-

nace, at a minimum pitch of 1/4" per foot of run, to prevent

accumulation of condensate.

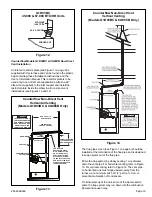

The 45,000 and 67,000 BTU/HR G1D93BC models

contain an inlet air assembly that uses two 22.5

°

elbows

that attach separately from the straight inlet pipe. This

allows the inlet pipe assembly to be removed if needed for

service.

Do not cement these elbows.

Refer to Figure 12

for detail of this inlet air assembly.

On initial start-up of the unit, some of the water used to

prime the trap system may run down into the combustion

blower and cause noise.

Do not cement air inlet pipe. Use high temperature

RTV silicone sealant so inlet pipe can be removed if

service is required.

For proper operation, the vent and air intake pipe

must be installed in the same pressure zone. There-

fore, in horizontal venting applications they must be

on the same side of the house within the parameters

shown in Figure 10.

Figure 11

Counterflow Direct Vent – Vertical Venting

(Models G1D93BC & CG90CB Only)

Counterflow Direct Vent

Horizontal Venting

(Models G1D93BC & CG90CB Only)

Figure 10

(CL

O

SE

D)

DRA

N

H

O

L

E

TH

RU.

59.69/

56.64

DO NOT INSTALL THE

RESTRICTOR PLATES IN

ANY DIRECT VENT

APPLICATIONS.

IMPORTANT

FLUE PIPE

THIS PIECE

IS OPTIONAL.

AIR INTAKE PIPE

18” *

RUN PITCH = 1/4”

PER FOOT MIN.

SEE TABLE FOR

PROPER PIPE SIZE.

AIR INLET

PIPE

6”

HEIGHT TO PROVIDE

12” CLEARANCE TO

MAX. SNOW LEVEL.

PVC COLLARS

THE VENT SYSTEM OF

THE FURNACE MUST BE

SELF-SUPPORTING AND

MUST NOT APPLY ANY

WEIGHT LOAD TO THE

COMBUSTION BLOWER.

CAUTION

CONDENSATE

COLLAR

VENT PIPE

* The 18" dimension is the

minimum recommended height

for extremely cold areas. In

these areas, moisture in the

flue gases may condense and

freeze on the air intake if this

height is reduced. In milder

climates, this may be reduced

to a minimum of 6". Height may

be increased as needed

provided total length is not

exceeded.

THIS PIECE

IS OPTIONAL.

INTAKE PIPE

FLUE PIPE

3” MIN. - 48” MAX.

Overhead View