# 45466K003

Page 3

INSTALLATION

These instructions must be placed on or near the

furnace in a conspicuous place.

The furnace design is certified by CSA International as a

Category IV furnace in compliance with the latest edition

of American National Standard Z21.47/CSA Standard 2.3

for Gas-Fired Central Furnaces, for operation with natural

gas or propane. Consult the rating plate on the furnace for

gas type before installing.

The maximum hourly heat loss of space shall be calcu-

lated in accordance with the procedure described in the

current manuals of Air Conditioning Contractors of

America, or by any other recognized method which is

suitable for local conditions, provided the results obtained

are in substantial agreement with, and not less than, those

obtained using the procedure described in the manuals.

G1D91BU, G1D93BU, and CG90UB models shall be

installed only as

upflow

furnaces. G1D93BC and

CG90CB models shall be installed only as

counterflow

(downflow) furnaces.

Inspection of Shipment

This furnace is shipped in one package, completely

assembled and wired.

The thermostat is shipped in a

separate carton when ordered.

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is found, it should be noted

on the carrier

’

s freight bill. Damage claims should be filed

with the carrier immediately. Claims of shortages should

be filed with the seller within 5 days.

Location

To provide proper operation and satisfactory performance,

care must be taken in choosing the location for this furnace.

The atmosphere in which the furnace operates must be free

of contaminants such as chlorides and sulfates.

The furnace must be installed so that electrical compo-

nents are protected from water.

Unit must be level for

proper condensate drainage.

All models are suitable for closet or utility room installation.

The furnace is suitable for installation in buildings con-

structed on-site. The furnace should be centralized in

respect to the heat distribution system as much as

practicable. When installed in a utility room, the door

should be wide enough to allow the largest part of the

furnace to enter, or permit the replacement of another

appliance, such as a water heater.

A gas-fired furnace for installation in a residential garage

must be installed so the burner(s) and the ignition source

are located not less than 18" above the floor. The furnace

is to be located or protected to avoid physical damage by

vehicles.

If the furnace is to be installed in an attic or other

insulated space, it must be kept free and clear of

insulating materials.

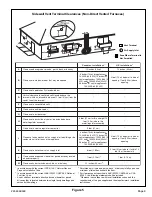

Clearances

All servicing and cleaning of the furnace can be performed

from the front. If installed in a closet or utility room, provide

18" clearance in front for service if the door to the room is

not in line with the front of the furnace.

Refer to Table 1 on page 4 for the minimum clearances to

combustibles required for construction and proper unit

operation.

Accessibility clearances must take precedence over

fire protection clearances.

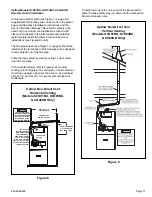

Upflow models (G1D91BU, G1D93BU, & CG90UB) may be

installed on wood flooring but shall not be installed directly

on carpeting, tile, or any other combustible material.

Counterflow models (G1D93BC & CG90CB) are certified

for installation on combustible flooring provided a special

base assembly is used. (Refer to the

Duct Connection –

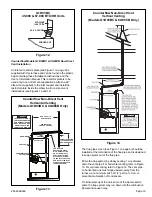

The condensate drain on this furnace is

incorporated within the furnace and must be

primed before start-up.

The condensate

system must not be exposed to tempera-

tures under 32°F.

Use of heat tape is per-

missible provided the rate temperature of the

tape

does not exceed 155°F.

CAUTION

Do not use the furnace as a heater in a

building under construction. The furnace can

be severely damaged due to the abnormal

environment caused by construction. Chlo-

rides from sources such as paint, stain, or

varnish; tile and counter cements; adhesives;

and foam insulation are abundant in a struc-

ture under construction and can be highly

corrosive. Low return air temperature can

cause condensation in the furnace and other

damage that can shorten the life of the unit.

CAUTION