# 45466K003

Page 5

Canada, see CSA B149.1, Natural Gas and Propane

Installation Codes (latest edition).

4. The following types of installation may require

outdoor

air

for combustion, due to chemical exposures:

•

Commercial buildings

•

Buildings with indoor pools

•

Furnaces installed in laundry rooms

•

Furnaces installed in hobby or craft rooms

•

Furnaces installed near chemical storage areas

5. Exposure to the following substances in the combustion

air supply may also require

outdoor air

for combustion:

•

Permanent wave solutions

•

Chlorinated waxes and cleaners

•

Chlorine-based swimming pool chemicals

•

Water softening chemicals

•

Deicing salts or chemicals

•

Carbon tetrachloride

•

Halogen-type refrigerants

•

Cleaning solvents (such as perchloroethylene)

•

Printing inks, paint removers, varnishes, etc.

•

Cements and glues

•

Antistatic fabric softeners for clothes dryers

•

Masonry acid washing materials

•

Chlorinated laundry products

•

Hydrochloric acid

Venting

The high efficiency of this furnace is accomplished by the

removal of both sensible and latent heat from the flue gases.

The removal of latent heat results in the condensation of

moisture in the flue gases. This condensation occurs in the

secondary heat exchanger and in the vent system. There-

fore, this furnace requires special venting considerations

and the instructions must be followed to insure proper

operation. All venting must be in accordance with the codes

having jurisdiction in the area and these instructions.

Upflow models G1D91BU, G1D93BU, and CG90UB and

counterflow models G1D93BC and CG90CB can be

installed as either direct vent or non-direct vent units. A

direct vent (two pipe) installation requires that all the air

necessary for combustion be supplied from outside the

dwelling through an air intake pipe. A non-direct vent (one

pipe) installation uses air from inside the dwelling for

combustion.

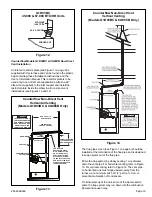

The furnace is shipped with the air inlet pipe terminated to

the top panel for either inside or outside combustion air. An

inlet air restrictor plate (see Figure 1) is supplied with this

furnace and can be found in the plastic bag containing these

Installation Instructions and the User

’

s Information Manual.

For installations using inside air for combustion (non-direct

vent), attach a 90

°

elbow (not supplied) to the inlet coupler

and install the restrictor plate inside the elbow (see Figures

8 and 9 on page 11 or Figures 13 and 14 on page 13).

If at any time in the future the installation of

this furnace is changed to require outside

fresh air for combustion, the inlet air restrictor

plate must be removed. Failure to remove the

inlet air restrictor could cause improper

operation that can result in a fire hazard or

carbon monoxide injury.

WARNING

Also included in the plastic bag containing the inlet air

restriction plate is a flue pipe screen (see Figure 1). In all

installations, this screen should be installed at the termi-

nation of the flue pipe and is designed to keep objects out

of the flue pipe.

For either type of installation (direct or non-direct vent),

special venting considerations must be followed. Refer to

the proper section in pages 10

–

13 for the type of furnace

and venting being installed.

The venting system must be supported with mounting

straps to prevent any weight load from being applied to the

vent blower. Horizontal vent pipe must be supported every

5' and vertical pipe should be supported every 10' to

prevent sagging and provide rigid support.

When a furnace is installed as direct vent, provisions for

ventilation air should follow the same requirements as if

installed as non-direct vent. Proper ventilation air is

necessary to maintain furnace component temperatures

within acceptable limits.

All vents passing through floors, ceilings, and walls must

be installed in accordance with National Fuel Gas Code,

ANSI Z223.1/NFPA 54 (latest edition).

Inlet Air Restrictor Plate

Flue Pipe Screen

The inlet air restrictor plate

must

be installed in all

installations using inside air

for combustion (non-direct

vent).

The flue pipe screen

should be installed at the

termination of the flue pipe

in all installations.

Figure 1