# 45466K003

Page 6

Category IV Furnace Limitations

This furnace shall

not

be connected to any Type B, BW, or

L vent or vent connector and shall

not

be connected to

any portion of a factory-built or masonry chimney.

This

furnace is not to be common vented with any other

appliance. The vent pipe must not be connected to a

chimney flue serving a separate appliance designed

to burn solid fuel.

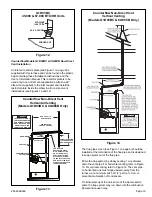

Vent Pipe Size and Length

The vent pipe and air intake pipe (in direct vent installa-

tions) should be sized in accordance with the information

found in the appropriate table in Figure 3. One 90

°

elbow

is equivalent to 5' of pipe. Two 45

°

elbows are equivalent

to one 90

°

elbow. The minimum length certified for use

with this furnace is 5' and one elbow, not including the

vent and air intake terminals.

In the event that the pipe length is in between the lengths

listed in the table, use the next larger length listed. For

example, if a length of pipe needed to install the furnace is

27', use the diameter values for the 30' row in the tables.

In all applications where the flue pipe is run through

an unconditioned space, 1/2

"

Armaflex or equivalent

must be used over the pipe. In extreme cold climates,

3/4

"

Armaflex is recommended.

Materials

All pipe, fittings, primer, and solvent cement must conform

with American National Standard Institute and the Ameri-

can Society for Testing and Materials (ANSI/ASTM)

standards. The solvent shall be free flowing and contain

no lumps, undissolved particles, or any foreign matter that

adversely affects the joint strength or chemical resistance

of the cement. The cement shall show no gelation, stratifi-

cation, or separation that cannot be removed by stirring.

Refer to Table 2 for approved piping and fitting materials.

cement is recommended. Metal or plastic strapping may be

used for vent pipe hangers.

When making ABS joints, pieces can be prepared with a

cleaner. When joining ABS to PVC materials, use PVC

solvent cement as specified in ASTM D3138.

Preferred fittings are DWV style or long sweep. Seal all joints

gas tight with appropriate cement. In areas where vent and

air intake pipes are exposed to abnormal stress or are

subject to damage, schedule 80 pipe should be used.

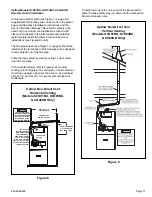

Concentric Vent Kit

A concentric vent kit (model ACVK2) is available for use

when installing this furnace as a direct vent furnace and the

air intake and vent pipe are to be run through the same hole,

whether horizontally through the wall or vertically through the

roof (see Figure 2). Refer to the instructions included with

the concentric vent kit for installation specifics.

Table 2

Piping and Fitting Specifications

The primers and solvents used must also meet ASTM

specifications. PVC primer is specified in ASTM F656. Use

PVC solvent as specified in ASTM D2564 and ABS solvent

cement as specified ASTM D2235. Low temperature solvent

Figure 2

2"

Nominal

Pipe Size

3.5"

18"

5"

1"

11"

Concentric Vent Kit Dimensions

g

n

i

t

t

i

F

d

n

a

g

n

i

p

i

P

l

a

i

r

e

t

a

M

M

T

S

A

n

o

i

t

a

c

i

f

i

c

e

p

S

C

V

P

0

4

e

l

u

d

e

h

c

S

)

e

p

i

P

(

5

8

7

1

D

C

V

P

0

4

e

l

u

d

e

h

c

S

)

e

p

i

P

e

r

o

C

r

a

l

u

ll

e

C

(

1

9

8

F

C

V

P

0

4

e

l

u

d

e

h

c

S

)

s

g

n

i

t

t

i

F

(

6

6

4

2

D

6

2

-

R

D

S

)

e

p

i

P

(

1

4

2

2

D

S

B

A

0

4

e

l

u

d

e

h

c

S

)

e

p

i

P

(

7

2

5

1

D

S

B

A

0

4

e

l

u

d

e

h

c

S

)

s

g

n

i

t

t

i

F

(

8

6

4

2

D

C

V

P

C

0

8

&

0

4

e

l

u

d

e

h

c

S

)

e

p

i

P

(

1

4

4

F

V

W

D

-

S

B

A

t

n

e

V

&

e

t

s

a

W

n

i

a

r

D

)

s

g

n

i

t

t

i

F

&

e

p

i

P

(

1

6

6

2

D

V

W

D

-

C

V

P

t

n

e

V

&

e

t

s

a

W

n

i

a

r

D

)

s

g

n

i

t

t

i

F

&

e

p

i

P

(

5

6

6

2

D