22

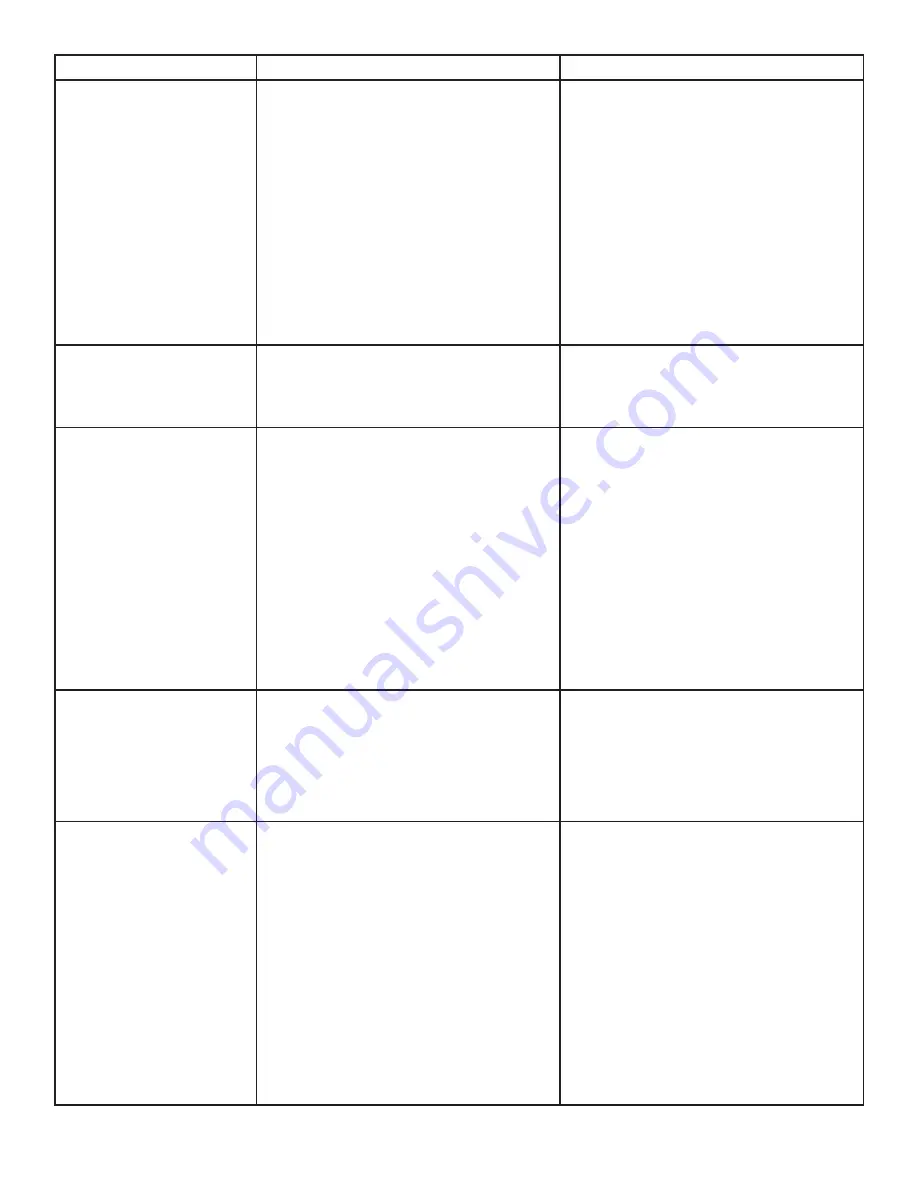

TROUBLE

CAUSE

REMEDY

Water only dispensed; no

syrup; or syrup only

dispensed, no water

1. Water or syrup shutoff on mounting block

not fully open.

2. Improper or inadequate water or syrup flow.

3. BIB supply too far from dispenser.

4. CO

2

pressure too low.

5. Stalled or inoperative BIB pump

6. Kinked line.

1. Open shutoff fully.

2. Remove valve from mounting block, open

shutoffs slightly and check water and syrup

flow. If no flow, check dispenser for

freeze-up or other problems. Ensure BIB

connection is engaged.

3. Check that BIB supply is within six (6) feet

of the dispenser.

4. Check the CO

2

pressure to the pump

manifold to ensure it is between 70 and 80

psi (0.483 and 0.552 MPa).

5. Check CO

2

pressure and/or replace pump.

6. Remove kink or replace line.

Syrup only dispensed. No

water, but CO

2

gas dispensed

with syrup.

1. Improper water flow to dispenser.

2. Carbonator pump motor has timed out.

1. Check for water flow to dispenser (see

Insufficient Water Flow on previous page).

2. Reset by turning the unit OFF and then ON.

Excessive foaming.

1. Incoming water or syrup temperature too

high.

2. CO

2

pressure too high.

3. Water flow rate too high.

4. Nozzle not installed correctly.

5. Nozzle and nozzle injectors not clean.

6. Air in BIB lines.

7. Poor quality ice.

8. High beverage temperature.

1. Correct prior to dispenser. Consider larger

dispenser or pre-cooler.

2. Adjust CO

2

pressure downward, but not less

than 70 PSI (0.483 MPa).

3. Re-adjust and reset ratio. Refer to “Adjust

Water Flow Rate & Syrup/Water Ratio”

Section.

4. Remove and reinstall properly.

5. Remove nozzle and clean injectors.

6. Bleed air from BIB lines.

7. Check quality of ice used in drink.

8. Check refrigeration system.

Warm drinks.

1. Restricted airflow.

2. Dispenser connected to hot water supply.

3. Dispenser capacity exceeded.

1. Check clearances around sides, top, and

inlet of unit. Remove objects blocking

airflow through grill.

2. Switch to cold water supply.

3. Add pre-cooler or replace with larger dis-

penser.

Circuit breaker tripping.

1. Valve wire harness shorted to itself or to

faucet plate.

2. PCB is bad.

3. Secondary wire harness is bad.

4. Transformer failure.

1. Detect short by disconnecting input fasten

to keylock and single pin connector. Restore

power if breaker doesn’t trip. Then valve

wire harness is shorted. If OK, reconnect.

2. Detect short by disconnecting J1

connector (24 VAC input) from PCB.

Restore power, if breaker doesn’t trip. Then

replace PCB. If breaker does trip, then PCB

is OK. Reconnect J1 connector.

3. If it does not trip, locate short in secondary

harness between transformer, PCB, and

valve wire harness.

4. Detect short by disconnecting both

transformer fastons and restore power. If

breaker does trip, replace transformer.