66

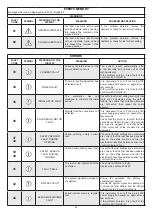

33) MEANING OF BUZZER WARNING SIGNALS

The control unit ET-LOGIC-B of the automation is equipped with a buzzer emitting a set of warning signals, whose meaning varies

according to the number of emitted beeps and to the signal duration.

WARNING SIGNAL (BEEP)

MEANING

5 short and fast BEEPS

Automation not set‑up when powered.

3 short BEEPS

Self-diagnosis failure on photocell PRJ38.

4 BEEP

Intervention on photocell PRJ38.

4 short BEEPS

Set-up cycle initial phase start warning.

Extended sound (3 seconds)

Signals the end of the initial set-up.

Extended and intermittent sound

(during motion)

The power limit that the automation can supply to the motor is

exceeded while the leaf is in motion. This signal is active if function

F40 = OFF.

To disable this warning set F40 to ON.

1 BEEP

After powering the automation (already started up before).

1 BEEP (before the opening)

Failed opening safety sensor test.

1 BEEP (before the opening)

Battery failure or low battery charge warning.

2 BEEPS (when the door is open)

Failed closing safety sensor test.

1 extended BEEP (1")

Detection of an internal system failure.

34) MAINTENANCE PROGRAM

To ensure that the automatic door keeps running safely over time, it is recommended to carry out the maintenance operations once every

6 months.

The installer can set the number of opening/closing cycles after which the message "PROGRAMMED MAINTENANCE" will appear on

the display of the selector ET‑DSEL (parameter P48).

Warning!

Before performing any operation on the automation, cut off the mains power supply.

•

Check that all screws are tight.

•

Check the belt's tension.

•

Clean the trolley sliding rail and the ground sliding guide.

•

Check that trolleys and leaves are properly aligned and that the door's final ledge is in correct position.

•

Check that the electric lock ‑ if any ‑ is properly fastened and that the mechanical release device operates properly.

•

Check connections and electric cables

•

Check leaf stability and make sure that movement is smooth and frictionless along the whole run.

•

Check that motion speeds, involved forces, and installed safety devices are working appropriately.

•

Clean sensors and check that presence detectors activate properly.

Once maintenance is completed, reset the partial cycle counter and the event memory (see paragraph "MAINTENANCE").

Warning!

Any potentially damaged or worn component must be replaced.

Make use of original spare parts only; for this purpose check LABEL Parts list.