12

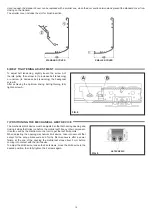

9) INSTALLATION DIMENSIONS

The transom must be fastened to a perfectly smooth flat surface, solid

enough to bear the weight of the leaf to be handled.

If the wall or the support do not meet these characteristics you will have

to provide a suitable tubular element, as the transom is not self-bearing.

Fasten the transom by means of M6 or equivalent steel dowels.

The fixing points must be distributed alternately between the reference

lines on the transom (L1 and L2) every 300mm.

The figure shows the fastening dimensions.

When drilling the transom and the wall, take care not to damage the

slideway rail (B1) as that would affect the operation and the quietness

of the automation.

After securing the transom, thoroughly clean the sliding area from any

drilling scraps.

TOOLS REQUIRED

Tape measure, drill, level, thin flat-head screwdriver, medium-

sized flat-head screwdriver, cross-head screwdriver, Allen

wrenches with handle (sizes 3 - 4 - 5 - 6), flat-head wrench 10.

FIG. 13

FIG. 14