1.

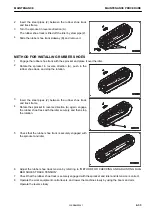

Set the machine to the greasing posture shown on the fig-

ure, lower the work equipment to the ground, and stop the

engine.

2.

By using a grease pump, pump in grease through the grease fittings shown by arrows.

(1) Arm and Bucket connection pin (1 place)

3.

After greasing, wipe off any old grease that is pushed out.

METHOD FOR CHECKING OIL LEVEL IN SWING MACHINERY CASE, ADDING

OIL

k

k

WARNING

Immediately after the engine is stopped, its parts and oil are still very hot, and may cause burn injury.

Accordingly, wait until they have cooled down before starting the work.

1.

Open the dirt cover (1) fully and it will be secured by the

cover support lever (2).

RKA68445

MAINTENANCE PROCEDURE

MAINTENANCE

4-44

WENAM00241

Содержание PC80MR-5E0

Страница 2: ......

Страница 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Страница 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Страница 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Страница 267: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1 WENAM00241...

Страница 343: ...SPECIFICATIONS 5 1 WENAM00241...

Страница 394: ...WENAM00241...

Страница 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Страница 411: ......

Страница 412: ......