Specifications

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-4

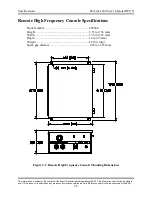

Gas Console Specifications

Stock Number (without Inova height control) ...................... 277080

Stock Number (with imperial Inova height control) ............. 277085

Stock Number (with metric Inova height control) ................ 277090

Height .................................................................................... 9 in (229 mm)

Width .....................................................................................25 in (635 mm)

Depth ..................................................................................... 23.8 in (605 mm)

Weight (with integrated Inova height control) ......................75 lb (34 kg)

Weight (without integrated Inova height control) ................ 60 lb (27 kg)

Gas Supply Requirements

Plasma gas types:

Mild Steel ...................................................... Oxygen or Air

Stainless Steel ............................................... Air or H17 (optional)

Aluminum ..................................................... Air

Shield gas types:

Mild Steel ...................................................... Oxygen or Air

Stainless Steel ............................................... Air or Nitrogen

Aluminum ..................................................... Air or Nitrogen

Preflow gas type ................................................... Air or Nitrogen

Plasma gas flow rate (maximum):

Oxygen or Air ............................................... 40 scfh (1132 liters/hour)

H17 ................................................................ 36 scfh (1019 liters/hour)

Shield gas flow rate (maximum):

Oxygen .......................................................... 19 scfh (538 liters/hour)

Air or Nitrogen .............................................. 150 scfh (4245 liters/hour)

Preflow gas flow rate (maximum) ....................... 25 scfh (708 liters/hour)

Inlet gas pressures (rated / maximum)

Oxygen .......................................................... 120 psi (8.3 bar) / 150 psi (10.3 bar)

Nitrogen ........................................................ 120 psi (8.3 bar) / 150 psi (10.3 bar)

Air ................................................................. 120 psi (8.3 bar) / 150 psi (10.3 bar)

H17 ................................................................ 120 psi (8.3 bar) / 150 psi (10.3 bar)

Oxygen and nitrogen should be supplied with a purity of at least 99.5%. H17

should be supplied with a purity of at least 99.995%.

A potential fire hazard

exists when cutting with oxygen. Flashback arrestors must be supplied to

prevent a possible fire from propagating back to the gas supplies.

Ensure that

oxygen lines remain free from contaminants such as oil and grease. The mixture

of such contaminants with oxygen presents an additional fire hazard. Compressed

air must be clean, dry, and oil-free and may be supplied from compressed

cylinders or from an air compressor. Be aware that shop air systems are prone to

oil and moisture contamination. If shop air is used, it must be cleaned to ISO

8573.1: Class 1.4.1. Specify dry air when using compressed cylinders. Breathing

quality air contains moisture and must not be used. 1/4” (inside diameter) hoses

are required for all inlet gas connections. Mating connectors are supplied with the

unit.

Quick-connect fittings must not be used.