Installation

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-3

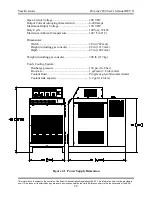

Power Supply Installation

The ProLine power supply should be lifted by a forklift or pallet jack. In order to prevent

damaging the power supply, the forks should be of adequate length to protrude on the far

side of the power supply. The proper location of the power supply will provide

dependable service and reduce periodic maintenance time. Choose a location that will

provide unrestricted air movement into and out of the power supply. Maintain

at least 24

inches

of space on

all

sides of the unit. The location should subject the power supply to

the least amount of dust, dirt, moisture, and corrosive vapors. The surface on which the

power supply is located should have a grade of no greater than 10º to eliminate the risk of

toppling over. The power supply must be cleaned as often as necessary to prevent the

accumulation of metallic dust inside the unit. See Figure 2-1 for power supply

dimensions.

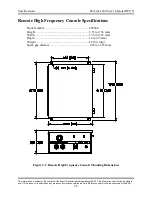

Remote High Frequency Console Installation

The Remote High Frequency (RHF) Console should be mounted in a convenient location

that is away from other electronic control devices. The high voltage, high frequency

signal generated inside the unit can interfere with the operation of certain control

systems. The RHF console is usually mounted on the gantry of the cutting machine or on

the cutting table. See Figure 2-2 for RHF console mounting dimensions.

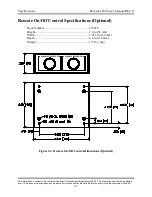

Torch Installation

The ProLine 2200 torch must be installed on the positioner of an arc voltage control

capable of maintaining the cutting arc voltage within 1 arc volt. The arc voltage must be

adjustable in 1 arc volt increments. The positioner must be rigid to ensure cut quality and

a torch collision sensor is highly recommended. See Figure 2-3 for torch mounting

dimensions.

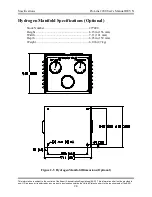

Primary Power Connection

** Before connecting primary power, check the data plate to verify the voltage

required by the ProLine power supply **

A primary disconnect switch, switching all ungrounded supply conductors, should be

provided for each ProLine power supply. The disconnect switch should be located as

close as possible to the power supply so it can be turned off quickly in case of an

emergency.

The disconnect switch should be equipped with time delay fuses only

.

The magnetic inrush current of the power supply will cause fast acting fuses to blow.

The disconnect switch should be sized according to local and national codes. The rating

must meet or exceed the continuous rating of the fuses used. See the following chart for

recommended fuse sizes: