SECTION 5 - BASIC HYDRAULICS INFORMATION & SCHEMATICS

31215031

5-43

13.

Rotate the capscrews evenly and progressively in rota-

tion to 5 ft. lbs. (7 Nm).

14.

Remove the cylinder rod from the holding fixture.

WHEN INSTALLING HYDROLOCK PISTON SEALS, ENSURE SEALS ARE

INSTALLED PROPERLY. REFER TO HYDROLOCKK PISTON SEAL INSTALLATION

FOR CORRECT SEAL ORIENTATION. IMPROPER SEAL INSTALLATION COULD

RESULT IN CYLINDER LEAKAGE AND IMPROPER CYLINDER OPERATION.

15.

Place new hydrolock seal and guidelock rings in the

outer piston diameter groove. (A tube, with I.D. slightly

larger than the O.D. of the piston is recommended to

install the solid seal).

16.

Position the cylinder barrel in a suitable holding fixture.

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE CYLINDER ROD,

HEAD, AND PISTON. AVOID PULLING THE ROD OFF-CENTER, WHICH COULD

CAUSE DAMAGE TO THE PISTON AND CYLINDER BARREL SURFACES.

17.

With barrel clamped secured and adequately support-

ing the rod, insert the piston end into the barrel cylinder.

Ensure that the piston loading o-ring and seal ring are

not damaged or dislodged.

18.

Continue pushing the rod into the barrel until the cylin-

der head gland can be inserted into the barrel cylinder.

19.

Secure the cylinder head gland using the capscrews.

Torque capscrews to 18 ft. lbs. (25 Nm).

20.

After the cylinder has been reassembled, the rod should

be pushed all the way in (fully retracted) prior to the re-

installation of any holding valve or valves.

21.

If applicable, install the cartridge-type holding valve and

fittings in the rod port block, using new o-rings as appli-

cable. Torque valves to 50-55 ft. lbs. (68-75 Nm).

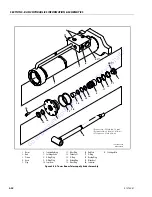

Figure 5-83. Hydrolock Piston Seal Installation

Figure 5-84. Piston Seal Kit Installation

MAE33460

O-RING

HYDROLOCK

SEAL

GUIDELOCK

RING

BACKUP

RING

MAE33440

BARREL

PISTON

ROD

SPACER

HEAD

ROD

CAPSCREW

Figure 5-85. Rod Assembly Installation

Go

to

Discount-Equipment.com

to

order

your

parts