SECTION 5 - BASIC HYDRAULICS INFORMATION & SCHEMATICS

5-42

31215031

2.

Use a soft mallet to tap a new wiper seal into the appli-

cable cylinder head gland groove. Install a new wear

ring into the applicable cylinder head gland groove.

3.

Place a new o-ring and backup seal in the applicable

outside diameter groove of the cylinder head.

4.

Carefully install the head gland on the rod, ensuring that

the wiper and rod seals are not damaged or dislodged.

Push the head along the rod to the rod end,

as applicable.

5.

Carefully slide the piston spacer on the rod.

6.

Using suitable protection, clamp the cylinder rod in a

vise or similar holding fixture as close to piston as possi-

ble.

7.

Place a new o-ring and backup rings in the inner piston

diameter groove.

8.

Carefully thread the piston on the cylinder rod hand

tight, ensuring that the o-ring and backup rings are not

damaged or dislodged.

9.

Thread piston onto rod end and install the tapered

bushing.

NOTE:

When installing the tapered bushing, piston and mating

end of rod must be free of oil.

10.

Assemble the tapered bushing loosely into the piston

and insert capscrews through the drilled holes in the

bushing and into the tapped holes in the piston.

11.

Tighten the capscrews evenly and progressively in rota-

tion to 5 ft. lbs. (7 Nm).

12.

After the screws have been torqued, tap the tapered

bushing with a hammer (16 to 24 oz.) and brass shaft

(approximately 3/4 in. diameter) as follows:

a.

Place the shaft against the cylinder rod and in con-

tact with the bushing in the spaces between the

capscrews.

b.

Tap each space once; this means the tapered bush-

ing is tapped 3 times as there are 3 spaces between

the capscrews.

Figure 5-79. Wiper Seal Installation

Figure 5-80. Installation of Head Seal Kit

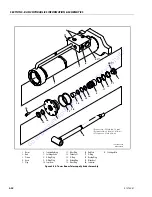

MAE33430

ROD

PISTON

TAPERED

BUSHING

CAPSCREW

Figure 5-81. Tapered Bushing Installation

Figure 5-82. Seating the Tapered Bearing

Go

to

Discount-Equipment.com

to

order

your

parts