INSTALLATION INSTRUCTIONS

Gas Furnace: (F/G)9MVE

440 01 4400 03

49

Specifications subject to change without notice.

Disassemble loose pipe fittings. Clean and cement using same

procedures as used for system piping. DO NOT CEMENT

POLYPROPYLENE FITTINGS.

Two

−

Pipe and Single

−

Pipe Terminations

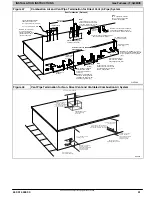

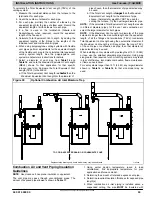

Single and two pipe vent must be installed as shown in

and

.

Maintain the required separation

distance between vents or pairs of vents as shown in

and

and all clearance shown in

.

NOTICE

RECOMMENDED SUPPORT FOR VENT

TERMINATIONS

It is recommended that rooftop vent terminations in

excess of 36 inches (1.0 M) in vertical length be

supported by EITHER the Direct Vent Termination Kit

shown in

or by field-supplied brackets or

supports fastened to the structure.

Cut the required number of holes in the roof or sidewall for vent

and (when used) combustion air pipes. Sidewall holes for

two-pipe vent terminations should be side-by-side, allowing

space between the pipes for the elbows to fit on the pipes.

Holes in the roof for direct

−

vent (two

−

pipe) terminations should

be spaced no more than 18

−

in. (457 mm) apart to help avoid

vent gas recirculation into combustion air intake.

Termination elbows will be installed after the vent and (if used)

combustion air pipe is installed.

Sidewall Terminations

Concentric Vent

NOTE

: Follow the instructions of the vent terminal

manufacturer. These instructions are provided as a reference,

only.

Determine an appropriate location for termination kit using the

guidelines provided in section “Locating The Vent Termination”

in this instruction.

1. Cut one 4

−

in. diameter hole for 2

−

in. kit, or one 5

−

in.

diameter hole for 3

−

in. kit.

2. Loosely assemble concentric vent/combustion air

termination components together using instructions in kit.

3. Slide assembled kit with rain shield REMOVED through

hole.

NOTE

: Do not allow insulation or other materials to accumulate

inside of pipe assembly when installing it through hole.

4. Locate assembly through sidewall with rain shield

positioned no more than 1

−

in. (25 mm) from wall as

shown in

5. Disassemble loose pipe fittings. Clean and cement using

same procedures as used for system piping. DO NOT

CEMENT POLYPROPYLENE FITTINGS.

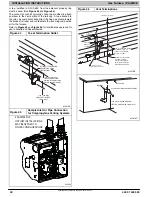

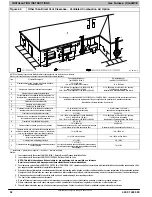

Two-Pipe and Single-Pipe Vent Termination

NOTE

: Follow the instructions of the vent terminal

manufacturer. These instructions are provided as a reference,

only.

NOTICE

RECOMMENDED SUPPORT FOR VENT

TERMINATIONS

It is recommended that side

−

wall vent terminations in

excess of 24 inches (0.6 M) in vertical length be sup-

ported by EITHER the Direct Vent Termination Kit in

or by field-supplied brackets or supports

fastened to the structure.

Determine an appropriate location for termination kit using the

guidelines provided in section “Locating The Vent Termination”

in this instruction.

1. Cut two holes, one for each pipe, of appropriate size for

pipe size being used.

2. Loosely install elbow in bracket (if used) and place

assembly on combustion

−

air pipe.

3. Install bracket as shown in

.

NOTE

: For applications using vent pipe option indicated by

dashed lines in

, rotate vent elbow 90

from position.

4. Disassemble loose pipe fittings. Clean and cement using

same procedures as used for system piping. DO NOT

CEMENT POLYPROPYLENE FITTINGS.

(Direct Vent / Two-Pipe System ONLY)

When two or more furnaces are vented near each other, two

vent terminations may be installed as shown in

and

, but next vent termination, or pair of vent

terminations, must be at least 36

−

in. (914 mm) away from first

two terminations. It is important that vent terminations be made

as shown in

gases.

Inducer Outlet Restrictor

(PSC models only)

To improve efficiency and operation of 40,000 BTUH input

models on very short vent systems, an inducer outlet restrictor

is required to be installed on the outlet of the inducer assembly.

The outlet restrictor is shipped in the loose parts bag.

To determine if the outlet restrictor is required, see

or

NOTE

: Failure to use an outlet choke when required may

result in flame disturbance or flame sense lockout.

To install the outlet restrictor:

1. Remove the vent elbow from the inducer outlet

2. Align the lock tabs on the outlet restrictor with the slots

on inside outlet of the inducer assembly.

3. Snap the outlet restrictor in place.

4. Re-install the vent elbow

5. Torque vent elbow clamp 15 lb

−

in.