38

LP- 428 REV. 9.2.14

Do not attempt to support the weight of gas piping with the boiler or its accessories. The gas valve and blower will not support the

weight of the piping. Failure to follow this warning could result in substantial property damage, severe personal injury, or death.

The gas connection on the boiler is 3

” for the Mod Con 1000 and 4” for the Mod Con 1700. It is mandatory that this fitting is used for

connection to a field fabricated drip leg as shown in the illustration above per the National Fuel Gas Code. You must ensure that the

entire gas line to the connection at the boiler is no smaller than the unit supplied connection.

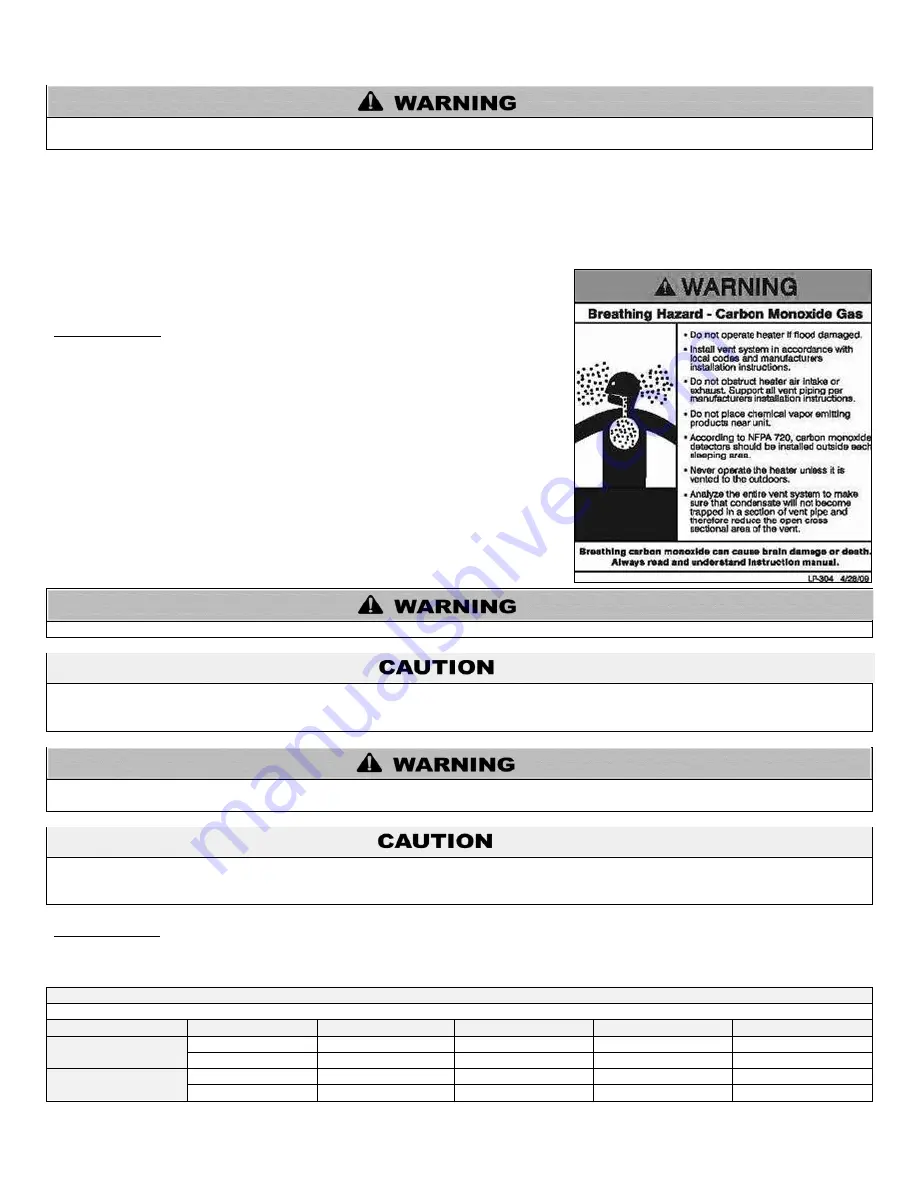

Once all inspections have been performed, the piping must be leak tested. If the leak test requirement is at a higher test pressure than

the maximum inlet pressure, you must isolate the boiler from the gas line. To do this, shut the gas off using factory and field-installed

gas cocks. Failure to do so may damage the gas valve. In the event the gas valve is

exposed to a pressure greater than ½ PSI, 14" w.c. (3.5 kPa), the gas valve must be

replaced. Never use an open flame (match, lighter, etc.) to check gas connections.

B. GAS PIPING

1. Run the gas supply line in accordance with all applicable codes.

2. Locate and install manual shutoff valves in accordance with state and local

requirements.

3. In Canada, the Manual Shutoff must be identified by the installing contractor.

4. It is important to support gas piping as the unit is not designed to structurally

support a large amount of weight.

5. Purge all gas lines thoroughly to avoid start up issues with air in the lines.

6. Sealing compound must be approved for gas connections. Care must be taken

when applying compound to prevent blockage or obstruction of gas flow which may

affect the operation of the unit.

Failure to apply pipe sealing compound as detailed above could result in substantial property damage, severe personal injury, or death.

CSA / UL listed flexible gas connections can be used when installing the boiler. Flexible gas connections have different capacities and

must be sized correctly for the connected boiler firing rates. Consult with the flex line supplier to assure the line size is adequate for the

job. Follow local codes for proper installation and service requirements.

Never use an open flame (match or lighter) to check for gas leaks. Use a soapy solution to test connection. Failure to use a soapy

solution test or check gas connection for leaks could result in substantial property damage, severe personal injury, or death.

Use a two-wrench method when tightening gas piping near the boiler and its piping connection: One wrench to prevent the boiler gas

line connection from turning; the second to tighten the adjacent piping. Failure to support the boiler gas piping connection could

damage the boiler beyond repair. Such damage IS NOT covered by warranty.

C. GAS TABLE

Refer to Table 10 to size the supply piping to minimize pressure drop between the meter or regulator and unit.

Maximum

capacity of pipe in cubic feet of gas per hour for gas pressures of .5 w.c. or less and a pressure drop of .3 inch w.c.

NATURAL GAS SUPPLY PIPING CAPACITY CHART

Schedule 40 Iron Pipe in Nominal Inch Size

(0.6 Specific Gravity Gas; 0.5” WC pressure drop)

MODEL

PIPE LENGTH

1 UNIT

2 UNITS

3 UNITS

4 UNITS

Mod Con 1000

100’

2”

3”

3”

4”

250’

2 ½”

3”

4”

4”

Mod Con 1700

100’

2

½”

4”

4”

5”

250’

3”

4”

5”

5”

Table 10

– Gas Supply Piping Size Chart for Mod Con Boilers

Содержание MODCON1000

Страница 40: ...40 LP 428 REV 9 2 14 E GAS VALVE Figure 22 Mod Con 1000 Gas Valve ...

Страница 46: ...46 LP 428 REV 9 2 14 Figure 25 Figure 26 Cascade Resistor Plug Installation Detail ...

Страница 47: ...47 LP 428 REV 9 2 14 Figure 27 Mod Con Cascade Master and Follower Wiring ...

Страница 48: ...48 LP 428 REV 9 2 14 Figure 28 Mod Con Internal Connection Diagram LP 428 K ...

Страница 70: ...70 LP 428 REV 9 2 14 Figure 31 MOD CON 1000 External Parts Blowout ...

Страница 71: ...71 LP 428 REV 9 2 14 Figure 32 MOD CON 1700 External Parts Blowout ...

Страница 72: ...72 LP 428 REV 9 2 14 Figure 33 ...

Страница 73: ...73 LP 428 REV 9 2 14 Figure 34 LP 445 S ...

Страница 74: ...74 LP 428 REV 9 2 14 Figure 35 LP 428 V ...

Страница 75: ...75 LP 428 REV 9 2 14 Figure 36 ...

Страница 78: ...78 LP 428 REV 9 2 14 ...

Страница 79: ...79 LP 428 REV 9 2 14 ...

Страница 80: ...80 LP 428 REV 9 2 14 MAINTENANCE NOTES ...