10

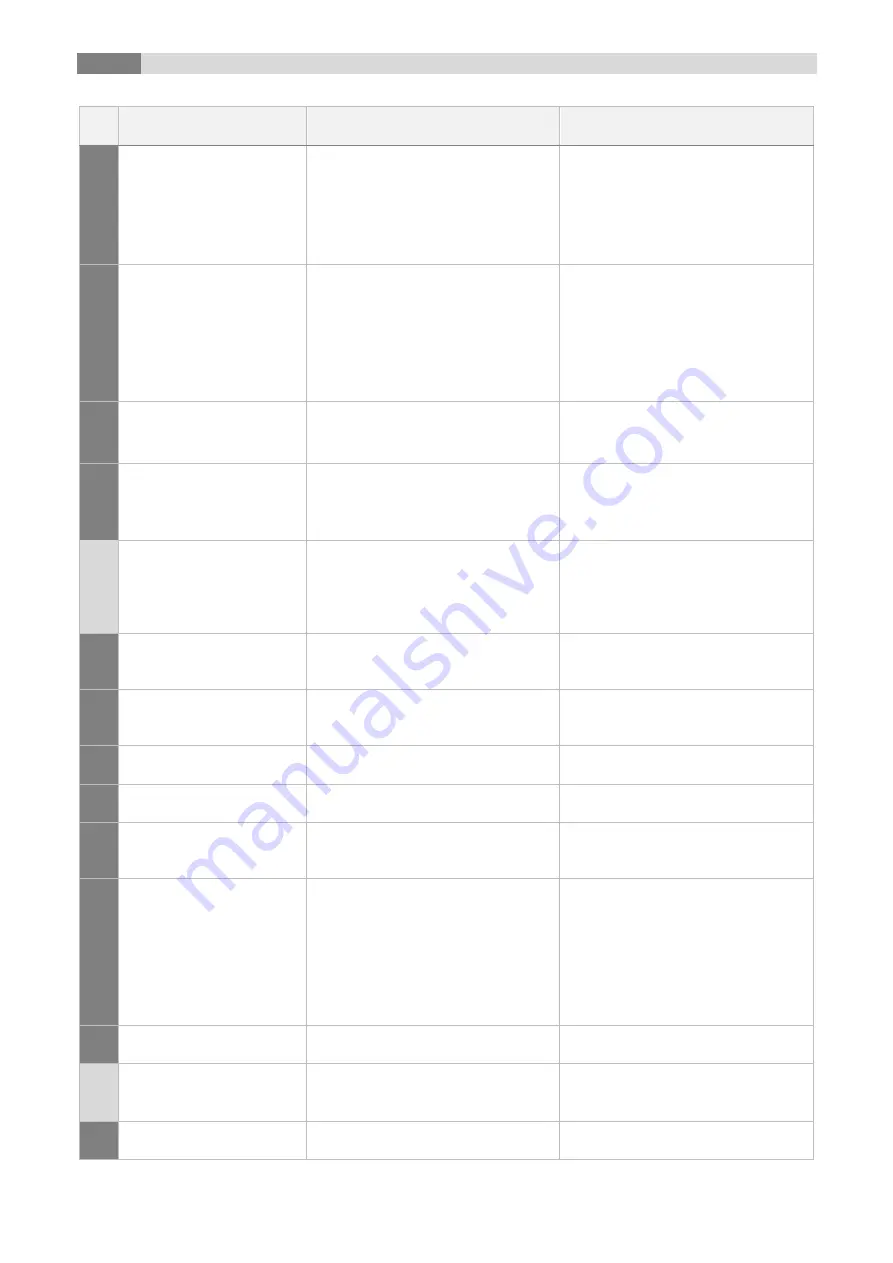

Fault reports and their corrections

72

No. Fault report

Cause of fault

Fault correction

063

OPEN BFP

if BFP-Open-Contact is not reached

during activation

▪

Check BFP-motor

▪

Check fuel temperature

▪

Clean intermediate hopper level

sensor

▪

Check drive arm

▪

✆

- contracting party

064

CLOSE BFP

Failure during burn back flap closing

▪

Check BFP-motor

▪

Check fuel temperature

▪

Clean intermediate hopper level

sensor

▪

Check drive arm

▪

✆

- contracting party

065

CONTACTS BFP

Failure at burn back flap end switch

▪

✆

- contracting party

▪

Carry out check BFP by specialist

personnel

066

IGNITION

Heat supplier didn´t ignite fuel within

15 minutes

▪

Check fuel level

▪

Check burning parameters, adjust

asadapt

▪

Check fuel level during firing

067

FIRE OUT

if no combustion is detected

▪

Check fuel level

▪

Check burning parameters, adjust

asadapt

▪

Clean intermediate hopper level

sensor

068

TEMP. CONTROL

Fuel storage room temperature

sensor has exceeded the maximum

permissible temperature

▪

Check fuel storage room

▪

Alarm fire brigade in case of fire

069

STL

Boiler temperature has exceeded

the maximum permissible boiler

temperature

▪

Cool down boiler (< 75 °C)

▪

Quit STL

070

LAMBDA FUEL

when Lambda material correction is

at upper or lower limit (30 minutes)

-

071

LAMBDA FUEL

if lambda probe value does not

change

✆

- contracting party

073

LAMBDA CALIBRATION

if calibration out of range or if other

error occurs during calibration and

aborts

✆

- contracting party

076

Standard Fuels

if

1) Pre-filling / Ignition insert can not

be performed because no fuel

2) Failure “FIRE OUT” occurs for

the second time within 2 hours.

3) during operation intermediate

hopper is not full despite power

reduction

▪

Check fuel level

▪

Check burning parameters, adjust

asadapt

▪

Clean intermediate hopper level

sensor

▪

System must be started manually

077

Additional input

Additional input (e.g.: system

pressure, CO-sensor) active

▪

Check failure at additional input

aggregate

078

NIVEAU LEVEL

Active intermediate hopper level

sensor; low fuel level at

intermediate hopper

▪

Check fuel level

▪

Check discharge system (motor,

screw, springs)

080

MP ROOM DISCHARGE

if digital input MP room discharge

responding

▪

Check discharge system (motor,

screw, springs) to debris

Содержание firematic PELLET 120

Страница 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system firematic PELLET 120 201 ...

Страница 19: ...Temperature manager 8 19 Fig 8 6 Example temperature manager when time mode without difference ...

Страница 84: ...15 Annex 84 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Страница 85: ...Annex 15 85 Hydraulic recommendation 2 ...

Страница 86: ...15 Annex 86 15 2 Solar module Program 1 ...

Страница 87: ...Annex 15 87 Program 2 ...

Страница 88: ...15 Annex 88 Program 3 ...

Страница 89: ...Annex 15 89 Program 4 ...

Страница 90: ...15 Annex 90 Program 5 ...

Страница 91: ...Annex 15 91 Program 6 ...

Страница 92: ...16 Notes 92 16 NOTES ...

Страница 93: ...Notes 16 93 ...