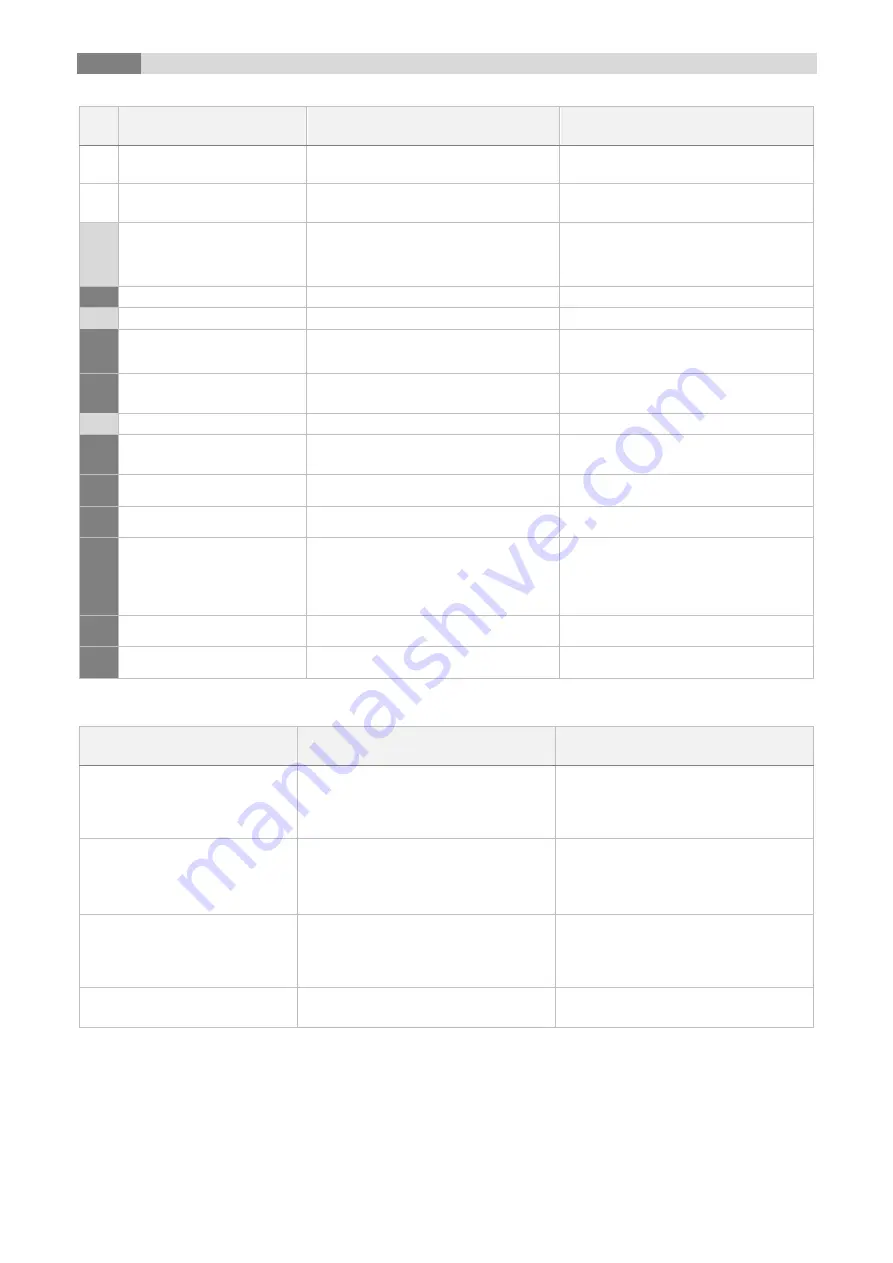

10

Fault reports and their corrections

74

No. Fault report

Cause of fault

Fault correction

129

Suction turbine-HOURS

-Exceeding the pellet-sucker interval

time (400h)

▪

execute maintenance

130

ignition fan - hours

if ignition fan operating hours have

been exceeded

▪

execute maintenance

133

FAULT CENTR. ASH

SYS.

Ash discharge did not clean

repeatedly; ash container full; debris

block ash screw; motor defect

▪

Empty ash container

▪

Remove debris

▪

✆

- contracting party

180

KAS CONNECTION

No connection to cascade

Check cascade connection

181

KAS OFFLINE

Boiler is not available to cascade

Establish data connection

182

KAS ALARM

Leading boiler couldn't be started or

got stopped

▪

Start leading boiler

✆

- contracting party

189

KAS CHKDATA

Cascade parameter is not in the

specified range

▪

Restart T-Control

▪

Check cascade parameter

199

CPU UPDATE

Software-update installed

▪

Reboot of the T-Control

249

AUTOREBOOT 2

The controller has restarted due to

an overload

▪

Reboot of the T-Control

▪

Adjusting network configuration

250

AUTOREBOOT 24

Software-monitoring fault

▪

✆

- contracting party

251

AUTOREBOOT 50

Software-monitoring fault

▪

✆

- contracting party

252

AUTOREBOOT 51

Software-monitoring fault

•

FORMAT USB-

STICK “via T-

Control -> if it does not work, the

USB stick is defective

▪

✆

- contracting party

253

AUTOREBOOT 67

Software-monitoring fault

▪

✆

- contracting party

254

AUTOREBOOT 68

Software-monitoring fault

▪

✆

- contracting party

10.1

Not indicated faults

Fault

Cause of fault

Fault correction

Boiler output gradually

decreases

Ash/slag on the grate; fly ash

container is full; heat exchanger

heavily clogged/sooted; inferior

quality fuel

Reduce cleaning intervals or clean

manually; empty the fly ash

container; clean heat exchanger

Desired operating temperature

is not reached

Inferior quality fuel;

previous boiler output higher than

current boiler output;

fuel level too low

Replace fuel if necessary, install

larger boiler; increase fuel level

Ash is emitted from the

chimney

Fly ash container full; fuel contains of

excessive finds or super fines; fan

speed too high; chimney draught to

high

Remove fly ash; replace fuel if

necessary or retrofit flue gas

deduster; reduce speeds; retrofit

chimney draught regulator

Deflagrations

Fuel to dry

Fuel to fine

Use fuel according to specifications

Содержание firematic PELLET 120

Страница 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system firematic PELLET 120 201 ...

Страница 19: ...Temperature manager 8 19 Fig 8 6 Example temperature manager when time mode without difference ...

Страница 84: ...15 Annex 84 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Страница 85: ...Annex 15 85 Hydraulic recommendation 2 ...

Страница 86: ...15 Annex 86 15 2 Solar module Program 1 ...

Страница 87: ...Annex 15 87 Program 2 ...

Страница 88: ...15 Annex 88 Program 3 ...

Страница 89: ...Annex 15 89 Program 4 ...

Страница 90: ...15 Annex 90 Program 5 ...

Страница 91: ...Annex 15 91 Program 6 ...

Страница 92: ...16 Notes 92 16 NOTES ...

Страница 93: ...Notes 16 93 ...