Needle-to-Feed Timing Theory and Check

3

5

Check #1

Turn the hand wheel in

direction of motion. When the

presser bar height is set correctly

at 6mm and the presser foot is in

the regular up position, the feed

advance should be completed as

the needle point reaches the foot.

The hand wheel should never be

turned against the direction of

motion.

Feed advance should be

completed before the needle

enters the fabric.

Check #2

Turn the hand wheel in

direction of motion until the needle

point reaches the top of the needle

plate

in its downward motion

. At

this point the feed dogs should be

on their way down and be just

above the needle plate. The feed

dogs will continue down and be all

the way down as the needle

reaches its lowest position.

Continuing to turn the machine in

direction of motion, the feed dogs

will be a

t their highest position

again as the needle reaches its

highest posit

i

on. T

he hand wheel

should never be turned against the

direction of motion.

The feed dogs

should be down when the needle

is down and up when the needle

is up.

The following tests are best

done with the machine powered

on and with the stitch length

set at the longest setting (5mm)

Содержание HQ Stitch 710

Страница 1: ...Service Manual 05 29 18 HQ Stitch 710...

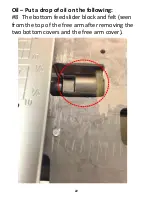

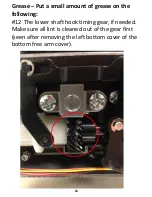

Страница 18: ...Oil Put a drop of oil on the following 1 The presser bar at the bottom bushing inside the left hinged cover 15...

Страница 24: ...Oil Put a drop of oil on the following 7 The hook felt under the needle plate and the bobbin case 21...

Страница 92: ...Appendix II Diagnostic Tests 89...