30

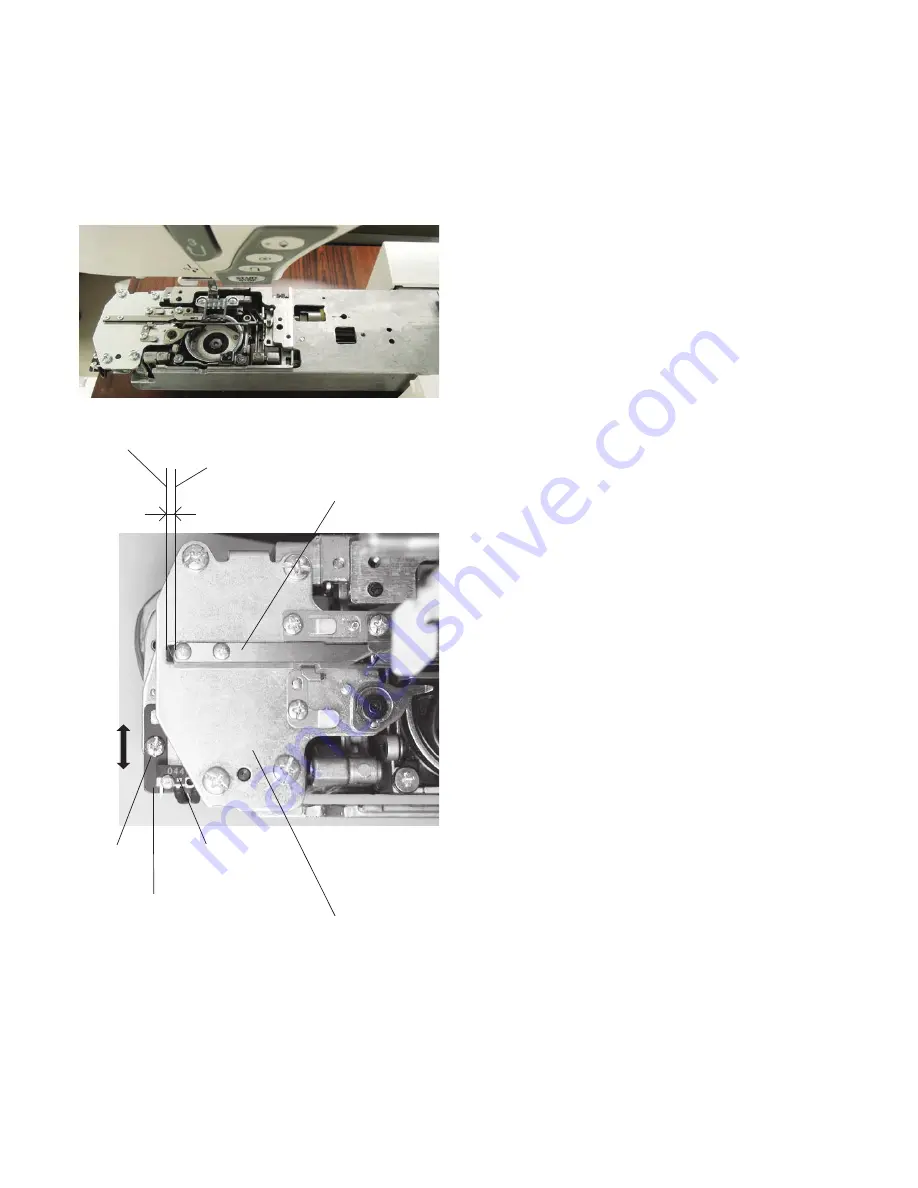

End of thread cutter plate slit

0.4 to 1.2 mm

Edge of moving cutter

Sensor plate

Setscrew

A

B

Thread cutter switch

Thread cutter base plate

Moving cutter

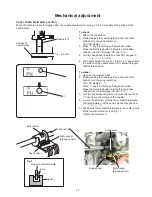

Mechanical adjustment

Thread cutter

The distance between the end of thread cutter plate slit and the edge of moving cutter should be in the range of 0.4 to 1.2

mm.

To check:

1. Remove the bed cover and free arm cover (see page 3, 4).

2. Turn the power switch off. Slide the moving cutter to the

right with your finger.

3. Turn the power switch on.

The moving cutter motor is initialized, and moving cutter

moves to its home position automatically.

4. The distance between the edge of moving cutter and

the end of thread cutter plate slit should be

0.4 to 1.2 mm.

If not, follow the procedure below.

To adjust:

1. Loosen the setscrew on the sensor plate.

2. Adjust the distance between the end of thread cutter

plate slit and the edge of moving cutter to 0.8 mm by

moving the sensor plate in the direction of A or B.

Содержание HQ Stitch 710

Страница 1: ...Service Manual 05 29 18 HQ Stitch 710...

Страница 18: ...Oil Put a drop of oil on the following 1 The presser bar at the bottom bushing inside the left hinged cover 15...

Страница 24: ...Oil Put a drop of oil on the following 7 The hook felt under the needle plate and the bobbin case 21...

Страница 92: ...Appendix II Diagnostic Tests 89...