13--8--625

Page 36

SECTION 7

BELT DRIVE

DRIVE BELT TENSIONING -- This compressor pack-

age has an automatic drive belt tensioning system.

The belts are kept at the correct tension by the spring

(figure 7--1). In the upper end of the spring, the position

of the pin indicates the correct tension on the belts. The

pin should be free in the long groove in the body of the

spring. The belts are adjusted at the factory so that the

position of the pins is at the top edge of the groove.

When the pin touches the bottom edge of the groove,

the belts are worn out and need to be replaced.

Sheaves should align straight across the front with a

straight edge.

REPLACING THE COMPRESSOR BELTS -- Use the

following instructions when replacing the drive belts:

1.

Be certain the unit is off.

2.

Disconnect, tag and lockout the power supply to

the starter.

3.

Move the belt change handle (FIGURE 7--1) to

the bottom position.

Be careful when moving the belt

change handle to the bottom posi-

tion, the belt change handle is under

spring tension.

4.

Remove the old belts and install the new belts.

5.

Lift the handle up into the top position. When the

handle is in the top position, the new belts are au-

tomatically at the correct tension.

The spring tension is adjusted to the

correct value at the factory. Do not

change the tightness by turning the

adjusting nut.

REPLACING THE COMPRESSOR OR MOTOR

SHEAVE

1.

Be certain the unit is off and that no air pressure

is in the air/oil reservoir. The compressor package

will automatically blowdown in about 2 minutes.

FIGURE 7--1 -- DRIVE BELT TENSIONER

2.

Close the air service valve located after the com-

pressor package discharge.

3.

Disconnect, tag and lockout the power supply to

the starter.

4.

Remove the screws holding the sheave to the

package and screw them into the jackbolt holes.

5.

Tighten the screws evenly until the drive bushing

and sheave are loose. They can be removed from

the shaft by hand when loosened.

6.

When installing new sheaves and bushings, re-

move all protective grease from the bushing and

sheave. install the bushing into the sheave and

align the holes.

7.

Grease the mounting screws and lightly tighten

them. The position of the mounting screws are

shown in FIGURE 7--3, page 37. The threads are

in the sheave only.

8.

Clean the shaft and mount the sheave assembly.

When mounting the sheave assembly, the bush-

ing clamps to the shaft first, the sheave can still be

Содержание EFD-25 HP

Страница 13: ...13 8 616 Page 4 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Страница 14: ...13 8 616 Page 5 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Страница 30: ...13 8 625 Page 21 FIGURE 4 4 COMPRESSOR RUNNING FULLY LOADED...

Страница 32: ...13 8 625 Page 23 FIGURE 4 5 WIRING DIAGRAM 3 305865 Ref Drawing...

Страница 33: ...13 8 625 Page 24 FIGURE 4 6 WIRING DIAGRAM 3 305979 A Ref Drawing...

Страница 34: ...13 8 625 Page 25 FIGURE 4 7 WIRING DIAGRAM 3 305979 A Ref Drawing...

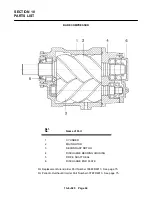

Страница 54: ...13 8 625 Page 45 AIREND GROUP...

Страница 60: ...13 8 625 Page 51 AIREND AND INLET FILTER ASSEMBLY...

Страница 62: ...13 8 625 Page 53 DRIVE GROUPS For list of Common Parts see page 54 For Drive Groups see pages 55 through 62...

Страница 72: ...13 8 625 Page 63 COOLING GROUP...

Страница 74: ...13 8 625 Page 65 CONTROL SYSTEM ASSEMBLY AND MOUNTING...

Страница 78: ...13 8 625 Page 69 CONTROL BOX 3 305979 A Ref Drawing...

Страница 80: ...13 8 625 Page 71 ENCLOSURE GROUP...