13--8--625

Page 29

humidity, etc.), it will be necessary to change the oil

more frequently. Operating conditions and the appear-

ance of the drained oil must be surveyed and the oil

change intervals planned accordingly by the user. Gar-

dner Denver offers a free oil analysis program with the

AEON lubricants and we recommend a sample be sent

in at 100 hours on a new unit.

DRAINING AND CLEANING OIL SYSTEM

Air/oil under pressure will cause

severe personal injury or death. Shut

down compressor, relieve system of

all pressure, disconnect, tag and

lockout power supply to the starter

before removing valves, caps, plugs,

fittings, bolts, and filters.

Always drain the complete system. Draining when the

oil is hot will help to prevent varnish deposits and carry

away impurities.

To drain the system, use one of the following methods:

1.

If the unit is not elevated high enough to use the

oil reservoir drain line to drain oil, a small hand,

electric or air operated pump should be used to

drain reservoir through the oil filler opening or from

the drain valve.

2.

If the unit is elevated so that the oil reservoir drain

can be used, empty the oil reservoir through the

drain valve to a suitable container or sump.

3.

If the drained oil and/or the oil filter element are

contaminated with dirt, flush the entire system:

reservoir, oil cooler, mixing valve and lines. In-

spect the oil separator elements for dirt accumula-

tion; replace if necessary. If a varnish deposit ex-

ists, contact the factory for recommendations for

removal of the deposit and prevention of varnish.

FILLING OIL RESERVOIR

Air/oil under pressure will cause

severe personal injury or death. Shut

down compressor, relieve system of

all pressure, disconnect, tag and

lockout power supply to the starter

before removing valves, caps, plugs,

fittings, bolts, and filters.

Compressor, air/oil reservoir, separa-

tion chamber and all piping and tub-

ing may be at high temperature during

and after operation.

1.

Be sure the unit is completely off and that no air

pressure is in the oil reservoir.

2.

Disconnect, tag and lockout the power supply to

the starter.

3.

Wipe away all dirt around the oil filler plug.

4.

Remove the oil filler plug and add oil as required

to return the oil level to the top of the white section

of the oil gauge.

5.

Install the oil filler plug and operate the unit for

about a minute allowing oil to fill all areas of the

system. Check for leaks.

FIGURE 5--3 -- OIL CHANGE INTERVAL

Discharge

AEON 2000

AEON 4000

AEON 9000SP

Temperature

Change Interval

Change Interval

Change Interval

Up to 180

_

F (82

_

C)

2000 hrs.

4000 hrs.

8000 hrs.

180

_

to 190

_

F (82

_

to 88

_

C)

1500 hrs.

3000 hrs.

6000 hrs.

190

_

to 200

_

F (88

_

to 93

_

C)

1000 hrs.

2000 hrs.

4000 hrs.

200

_

F+ (93

_

C)

500 hrs.

1000 hrs.

2000 hrs.

Содержание EFD-25 HP

Страница 13: ...13 8 616 Page 4 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Страница 14: ...13 8 616 Page 5 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Страница 30: ...13 8 625 Page 21 FIGURE 4 4 COMPRESSOR RUNNING FULLY LOADED...

Страница 32: ...13 8 625 Page 23 FIGURE 4 5 WIRING DIAGRAM 3 305865 Ref Drawing...

Страница 33: ...13 8 625 Page 24 FIGURE 4 6 WIRING DIAGRAM 3 305979 A Ref Drawing...

Страница 34: ...13 8 625 Page 25 FIGURE 4 7 WIRING DIAGRAM 3 305979 A Ref Drawing...

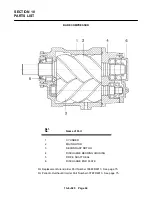

Страница 54: ...13 8 625 Page 45 AIREND GROUP...

Страница 60: ...13 8 625 Page 51 AIREND AND INLET FILTER ASSEMBLY...

Страница 62: ...13 8 625 Page 53 DRIVE GROUPS For list of Common Parts see page 54 For Drive Groups see pages 55 through 62...

Страница 72: ...13 8 625 Page 63 COOLING GROUP...

Страница 74: ...13 8 625 Page 65 CONTROL SYSTEM ASSEMBLY AND MOUNTING...

Страница 78: ...13 8 625 Page 69 CONTROL BOX 3 305979 A Ref Drawing...

Страница 80: ...13 8 625 Page 71 ENCLOSURE GROUP...