13--8--625

Page 39

SECTION 8

MAINTENANCE SCHEDULE

SERVICE CHECK LIST --

Air Filter -- Operating conditions determine frequency

of service. See “Air Filter,” Section 6, page 35.

Motor Lubrication -- Refer to Section 2, page 9, and

Maintenance Schedule Chart below.

Every 8 Hours Operation

1.

Check the reservoir oil level -- add oil if required.

See Section 5, page 28. If oil consumption is high,

refer to “Excessive Oil Consumption,” page 42.

2.

Observe if the unit loads and unloads properly.

3.

Check discharge pressure and temperature.

Every 125 Hours Operation

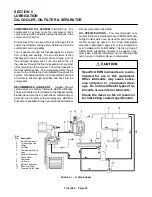

Check for dirt accumulation on oil/aftercooler core

faces and the cooling fan. If cleaning is required, clean

the exterior fin surfaces of the cores by blowing com-

pressed air carrying a nonflammable safety solvent in

a direction opposite that of the cooling fan air flow. This

cleaning operation will keep the exterior cooling sur-

faces clean and ensure effective heat dissipation.

Every 150 Hours Operation

Check/change the air filter.

Every 1000 Hours Operation

Change oil filter element.

Every 4000 Hours Operation

Change the compressor lubricant. UNDER ADVERSE

CONDITIONS, CHANGE MORE FREQUENTLY (re-

fer to “Oil Change Interval”, Section 5, page 29). Flush

system if required.

Every Year

1.

Check the relief valve for proper operation. See

Section 4, page 19.

2.

Change oil separator, see “Compressor Oil Sepa-

rator,” page 33, for further details (or 8 psid pres-

sure differential across the element).

MAINTENANCE SCHEDULE (See detail notes above)

Maintenance Action

Every

Every

Every

Every

Every

8

150

1000

4000*

Year

Hours

Hours

Hours

Hours

Check/Change Air Filter **

D

Change Oil Separator ***

D

Check Reservoir Oil Level ****

D

Check For Proper Load/Unload

D

Check Fault Indicator Lights

D

Check Dirt Accumulation on Cooler

D

Change Oil Filter Element & Clean Oil Return Strainer

D

Change Compressor Lubricant (AEON 4000) *

D

Check Relief Valve

D

Check Condition of Hoses

D

D

Check Operation of Condensate Removal

D

Solenoid Valve

*

See Oil Change Interval Chart, FIGURE 5--3, Section 5, Page 29, for specific lubricant life.

**

Check/change more often in dirty environments.

***

Also change when 8 psi

n

P across the element.

****

Must be checked when the compressor is stopped and the air/oil mixture is separated.

Содержание EFD-25 HP

Страница 13: ...13 8 616 Page 4 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Страница 14: ...13 8 616 Page 5 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Страница 30: ...13 8 625 Page 21 FIGURE 4 4 COMPRESSOR RUNNING FULLY LOADED...

Страница 32: ...13 8 625 Page 23 FIGURE 4 5 WIRING DIAGRAM 3 305865 Ref Drawing...

Страница 33: ...13 8 625 Page 24 FIGURE 4 6 WIRING DIAGRAM 3 305979 A Ref Drawing...

Страница 34: ...13 8 625 Page 25 FIGURE 4 7 WIRING DIAGRAM 3 305979 A Ref Drawing...

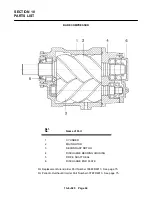

Страница 54: ...13 8 625 Page 45 AIREND GROUP...

Страница 60: ...13 8 625 Page 51 AIREND AND INLET FILTER ASSEMBLY...

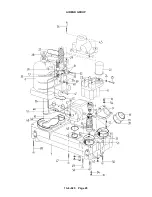

Страница 62: ...13 8 625 Page 53 DRIVE GROUPS For list of Common Parts see page 54 For Drive Groups see pages 55 through 62...

Страница 72: ...13 8 625 Page 63 COOLING GROUP...

Страница 74: ...13 8 625 Page 65 CONTROL SYSTEM ASSEMBLY AND MOUNTING...

Страница 78: ...13 8 625 Page 69 CONTROL BOX 3 305979 A Ref Drawing...

Страница 80: ...13 8 625 Page 71 ENCLOSURE GROUP...