Adjustment

Rev. A

4-3

4.1.2 Adjustment

Tools

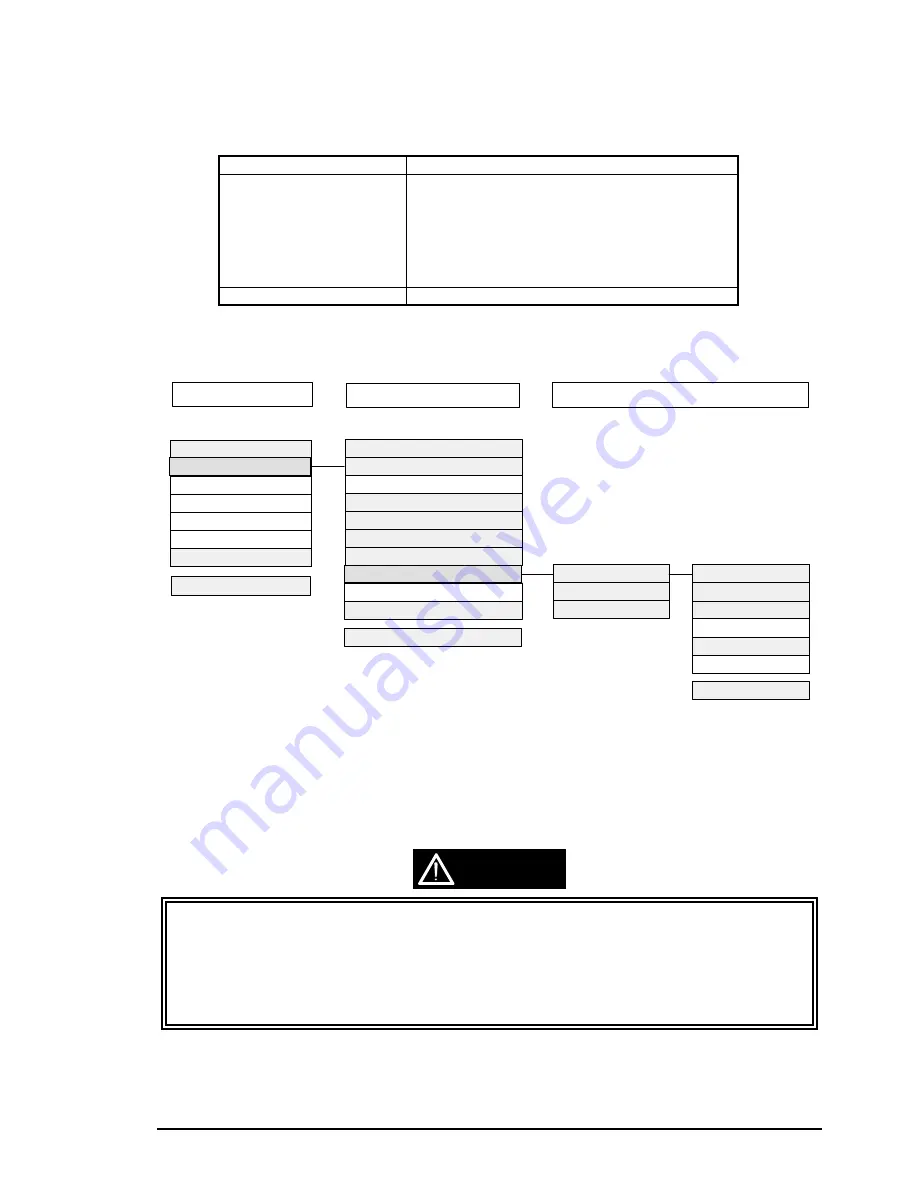

Table 4-2 shows the tools necessary to adjust this printer and the menus to be adjusted.

Tools for adjusting

Item to be adjusted

Program disk for adjustment

y

DOS system

y

GWBASIC

y

Adjustment program

(Version J70C00E)

Customer data writing operation

Initial ink charge (Ink charge)

Head voltage adjustment

Head angular adjustment

Black/color head vertical adjustment

Head gap adjustment

Bi-d adjustment

Thickness gauge (1.1 mm)

Platen gap adjustment

The program disk for adjustment consists of the total of 40 files such as DOS system, GWBASIC.EXE,

and adjusting programs. The adjusting menus in the program are as shown below:

Select the item in the light gray shaded box to perform necessary adjustment. You can proceed to the sub

menu thorough the item in the dark gray shaded box in the bold line. Selecting “All adjustment” in the

sub menu enables you to perform the following adjustments consecutively;“ Head angular adjustment”,

“BK.-M Linear adjustment” and “Head GAP adjustment/Bi-d adjustment” This section, however, only

refers to the individual adjustment methods.

;

During adjustment, values such as Customer data, head voltage value, head gap adjustment

value, and Bi-d adjustment value are written into the EEPROM at the specified timing as follows;

Customer data

:

At performing “Print Inspection”.

Head voltage value

:

When the “Return” key is pressed after entering the

values during “Write to the Head voltage value”

menu . The data is then transferred to the printer.

Bi-d/ Head gap adjustment value:

At performing “Print Inspection”.

Table 4- 2. Adjustment Tools

Input of Customer data

Adjustment/Print inspection

Change of center value

Input of comment

Change of date

Change of time

End

Select Menu :?_

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timing adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Input M/C No. : ?_

Black voltage value :

Color voltage value :

GOS paper print test

S.F. paper print test

O.Q.A print test

Cleaning

Return to the MENU

Letter paper print test

Select Menu :?_

Select Menu :?_

Main menu

Sub menu

Print inspection sub menu

Figure 4-1. Adjustment Program Menu

CAUTION

Содержание Stylus Color 800

Страница 1: ...EPSON COLOR INK JET PRINTER EPSON Stylus COLOR 800 SERVICE MANUAL SEIKO EPSON CORPORATION 4007371 ...

Страница 48: ......

Страница 56: ......

Страница 60: ......

Страница 154: ......

Страница 155: ......

Страница 156: ......

Страница 157: ......

Страница 158: ......

Страница 164: ......

Страница 173: ...EPSON Stylus 2 25 800 Rev A 6 6 Lubricate PF Roller Bushing 12 Figure 6 10 Lubrication Point 10 ...

Страница 184: ...Appendix Rev A A 9 A 3 Circuit Board Component Layout A 3 1 C202 MAIN Board Assembly Component Layout ...

Страница 185: ...EPSON Stylus 2 25 800 Rev A A 10 A 3 2 C202 PSB Board Assembly Layout A 3 3 C202 PSE Board Assembly Layout ...

Страница 187: ...EPSON SEIKO EPSON CORPORATION ...