12

SB300 FOSB FOR 300 MM WAFERS

User Manual | Entegris, Inc.

GENERAL USE INSTRUCTIONS

—

MANUAL ASSEMBLY

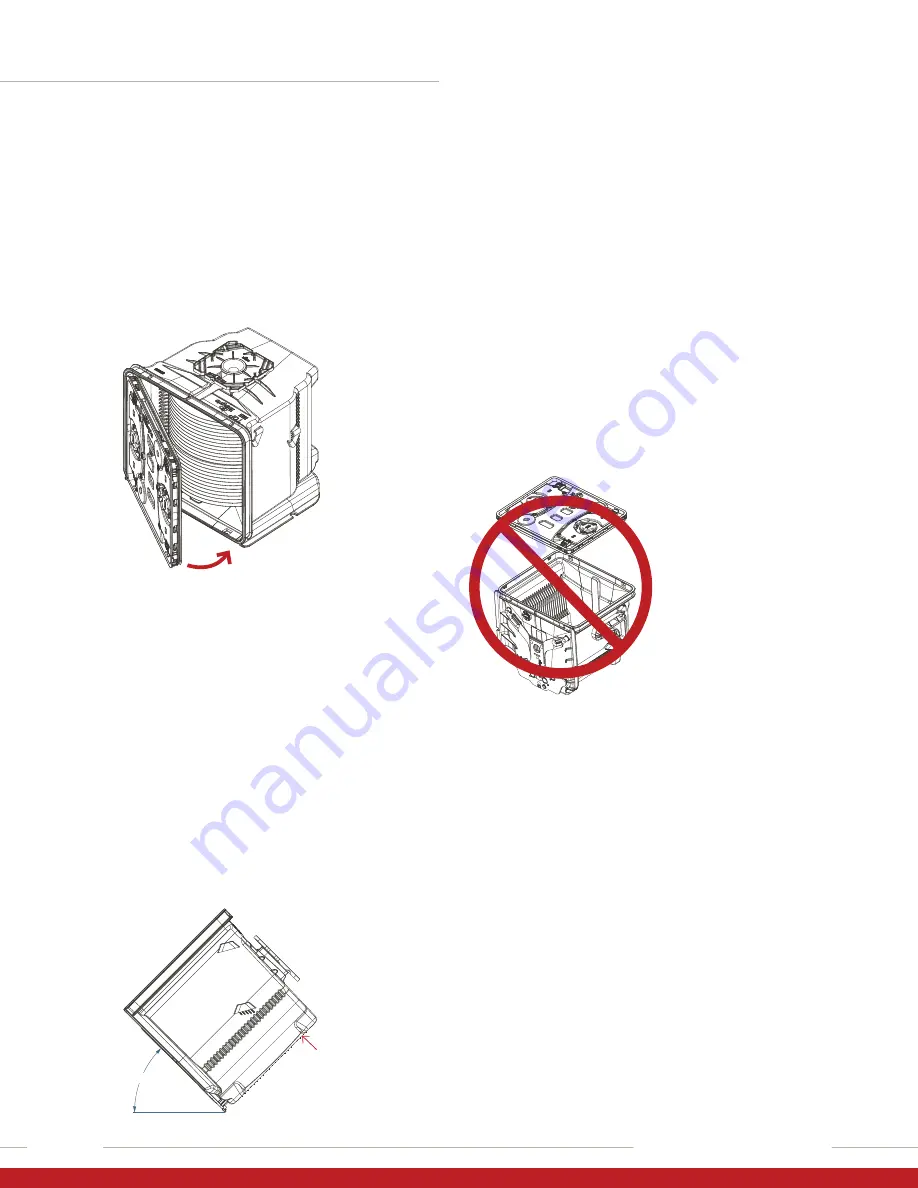

Proper manual assembly of the SB300 FOSB

door is accomplished by aligning the door’s right

or left vertical edge to the shipper box opening

(Figure 19).

1. Grip the door and shipper box along the vertical

edge (pivot edge) with one hand and rotate the

door until the wafer cushion contacts the wafers.

2. Latch the lock on the pivot edge first by rotating

the cam counterclockwise 90° using the tabs

available, manual latch keys, or optional D-rings.

Apply inward pressure to the opposite side of the

door until it is flush to the shipper box opening

and latch closed using the same procedure.

It is possible to assemble the SB300 FOSB when

seated on a horizontal kinematic coupling plate.

However to aid in assembly, Entegris recommends

that the shipper box be placed on an angled surface

of 15°–75° degrees as shown in Figure 20.

Both the bottom kinematic coupling surface and

back surfaces of the shipper box should be sup-

ported when on the angled work surface. Selection

of the most suitable angle to be used is dependent

on the height of the assembly workstation.

Errors are greatly minimized using this assembly

method. However, it is also required that a visual

inspection be performed after each assembly to make

sure the wafers are properly engaged with the door

cushion. This is most easily done when viewing the

wafers and cushion through the center of the door.

NOTE: Door assembly should never be attempted with

the shipper box on its back and the wafers in a completely

vertical position. This can cause cross slotting and wafer

breakage (Figure 21).

D-RING HANDLES

D-ring handles are used for manually disengaging the

door latches and for door retention. The D-ring

handles also incorporate automated key slots for

automated operation. The D-rings are simply lifted

and then rotated 90° clockwise to unlatch the door.

In this position, the D-rings provide a secure handle

for removing and replacing the door. When the door

is replaced in position, rotating the D-ring keys 90°

counterclockwise engages the door latches.

Recommendations

Make sure the door is properly seated before

engaging the latches.

Figure 19

Figure 20

15°–75°

Support to

prevent

tipping

Figure 21