ECOWATER

S Y S T E

M S

Service Information

30

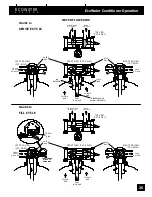

3 -- Valve Bypass

OUTLET

VALVE

INLET

VALVE

BYPASS

VALVE

water

flow

to conditioner

from conditioner

D

for

SERVICE:

-- Open

the

inlet

and

outlet valves.

-- Close

the

bypass valve.

D

for

BYPASS:

-- Close

the

inlet

and

outlet valves.

-- Open

the

bypass valve.

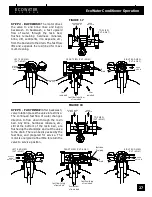

EcoWater Bypass Valves

CAUTION: ALWAYS relieve water pressure in the

EcoWater conditioner

,

as follows, before removing

parts from the valve or resin tank.

DE--

PRESSURIZE

1.

Put bypass valve(s) in bypass position.

2.

Do Manual Advance step1, page 28, (fill water to brine tank will

depressurize the resin tank).

PRESSURIZE

1.

Put bypass valve(s) in service position.

2.

Do Manual Advance steps 2--5, page 28, to return unit to service.

ALTERNATE METHOD

3--VALVE BYPASS

ECOWATER BYPASS VALVE

DE--

PRESSURIZE

1.

Close the INLET valve.

2.

Open HOT and COLD conditioned water

house faucets.

3.

Close the OUTLET valve and open the

BYPASS valve.

4.

Close all house faucets.

PRESSURIZE

1.

Open HOT and COLD house faucets.

2.

Close the BYPASS valve and open the

OUTLET valve.

3. Slowly,

open the INLET valve.

4.

Close all house faucets

DE--

PRESSURIZE

1.

Close the house main water supply valve.

2.

Open HOT and COLD

conditioned

water

faucets.

3.

Push or rotate the bypass valve handle to

bypass position.

Note: For hard water bypass to house fau-

cets, reopen the main water supply valve.

PRESSURIZE

1.

Open HOT and COLD house faucets

(main water supply valve open).

2.

Pull or rotate the bypass valve handle to

service position.

3.

Close all house faucets.

BYPASS

SERVICE

PUSH

IN

for

bypass

PULL

OUT

for

service

ECOWATER CONDITIONER OPERATION, ELECTRONIC CHECKOUT

ALWAYS MAKE THE INITIAL CHECKS FIRST

INITIAL CHECKS:

1.

Does the time display show the correct time of

day?

..

.If display is blank,

check power source to the Eco-

Water conditioner.

...

If time is incorrect,

power was off for over 2 days.

The conditioner resumes normal operation, when

power returns, but regenerations occur at the wrong

time.

...

If an error code shows

in the display (example: Er-

ror 3), go to AUTOMATIC ELECTRONIC DIAGNOS-

TICS, following.

2.

Are plumbing bypass valve(s) in

service

position

(all the way open or closed, as applies).

3.

Are the inlet and outlet pipes connected to the

EcoWater conditioner inlet and outlet respectively.

4.

Is the transformer plugged into a ‘‘live’’, grounded

wall outlet, and the power cable fastened securely?

5.

The valve drain hose must be free of kinks and

sharp bends, and not elevated over 8’above the

floor.

6.

Is there salt in the brine tank?

7.

Is the brine tubing connected? See FIG. 9, page

10.

8.

Press SELECT/EXIT (

¿

) to enter Primary Menu.

Move the cursor so that it is next to Set Hardness.

Press the SELECT/EXIT (

¿

) button once to display

the hardness setting. Be sure it is the correct setting

for the household’s water supply. ---- Make a hard-

ness test of the raw water and compare with the

hardness setting. Also test a conditioned water sam-

ple to verify if a problem exists. ----Press SELECT/

EXIT (

¿

) button to exit to Normal View Screens.

If you do not find a problem after making the initial

checks, do MANUAL INITIATED ELECTRONIC

DIAGNOSTICS, and the MANUAL ADVANCE RE-

GENERATION CHECK, pages 31 and 32.

E.A.S.E.:

EcoWater digital demand timers have the latest diagnostic technology. With E.A.S.E., or Electronic Au-

tomated Service Evaluation, a service person or homeowner can transmit operational data through the telephone,

to a personal computer (PC). The PC processes the data to determine if all electrical functions are working normally,

or helps to identify a problem should one occur. Ask your participating EcoWater dealer for more information on

this feature.