ECOWATER

S Y S T E

M S

EcoWater Conditioner Operation

24

ELECTRONICS

WATER METER:

The water meter consists of a turbine, turbine

mounting assembly, and sensor housing. It is lo-

cated at the valve outlet port, FIG. 6, page 9. As wa-

ter passes through and spins the turbine, 2 magnets

(in the turbine) cause a back--and--forth movement

of a switch in the sensor housing. This switch move-

ment sends a pulse to the faceplate timer.

FACEPLATE TIMER:

The faceplate timer is actually a small computer. As

it receives pulses from the water meter, it converts

them to gallons of water passing through the Eco-

Water conditioner. It multiplies this water usage in-

formation times the water hardness (prepro-

grammed into the timer) to continually calculate the

conditioned water capacity required. The computer

adjusts daily to water using habits, seeking to supply

conditioned water for the longest time, using the

least (and most efficient) amount of salt and water

to regenerate.

When the computer determines more capacity is

needed, it schedules a regeneration at the next re-

generation starting time (2:00AM, or as otherwise

preset). RECHARGE TONIGHT shows in the dis-

play to inform of the coming regeneration. During

vacations, etc., when you are not using water, the

EcoWater conditioner will not regenerate.

SERVICE, AND REGENERATION

The EcoWater conditioner is filled with a man-made

resin material, called the

resin bed.

The resin looks

somewhat like coarse sand, but the beads are round

and smooth. Resin has the ability to remove hard-

ness minerals from water by ion-exchange.

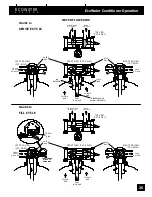

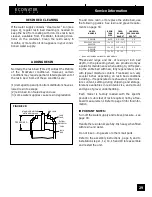

SERVICE (FIG. 14):

Hard water enters the EcoWater conditioner, passes

through the valve and down into the resin tank and

resin bed. As it passes through the bed, hardness

minerals are extracted from the water and held by

the resin beads. Conditioned water exits the resin

tank through the bottom distributor, flows up the in-

ternal standpipe, into the valve, and out to the house

pipes.

In time, the resin beads hold all the hardness miner-

als they can, and cleaning with a salt solution (brine)

is needed. Regeneration and recharge are words

used to describe this cleaning.

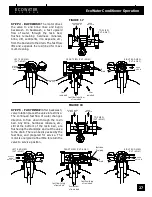

REGENERATION, OR RECHARGE:

The faceplate timer determines when a regenera-

tion is needed (see above). Regeneration starts at

2:00AM, or other preselected time, and consists of

5 different steps, or cycles. These are

fill, brining,

brine rinse, backwash,

and

fast rinse

.

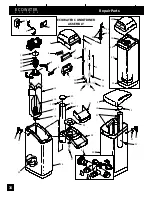

STEP 1 - FILL CYCLE (FIG. 15):

Salt, dissolved in

water, is called brine. Brine is the cleaning agent for

the resin bed. To make brine, water is needed in the

brine tank salt storage area. A controlled water flow

to the brine tank takes place during fill.

To enter fill, the EcoWater conditioner valve reposi-

tions slightly (motor energized). A valve passage

opens allowing

conditioned

water to flow through the

nozzle and venturi, to the brine valve, and into the

brine tank. Fill cycle length is regulated by the timer,

depending upon how much cleaning is needed to re-

move all hardness minerals, and restore 100% ca-

pacity.

continued, page 26