ECOWATER

S Y S T E

M S

Installation

10

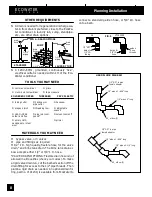

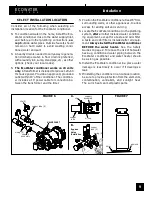

1. INSTALL BYPASS VALVE and/or COPPER

TUBES

IMPORTANT: The support assembly (FIG. 6) is fac-

tory installed. The bypass valve or outlet copper

tube will not insert properly if the support assembly

is reversed or not fully into the valve port.

a.

IF INSTALLING AN ECOWATER BYPASS

VALVE, put lubricated o--ring seals onto both bypass

valve ports (FIG. 6B). Carefully slide the bypass

valve into the softener valve and install the “C”clips.

b.

Slide a lubricated o--ring seal onto each of the

copper tubes. Carefully insert the copper tubes into

the bypass valve (FIG. 6B), or into the softener valve

(FIG. 6 and 6A). Then install the ‘‘C’’clips.

NOTE: For lubrication, use silicone grease ap-

proved for potable water supplies.

IMPORTANT: Be sure the bypass valve and/or

copper tubes are firmly held in place by the plas-

tic ‘‘C’’clips, and the clips are securely in place.

2. TURN OFF WATER SUPPLY

a.

Close the main water supply valve, near the well

pump or water meter.

b.

Shut off the electric or fuel supply to the water

heater.

c.

Open high and low faucets to drain all water from

the house pipes.

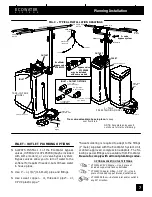

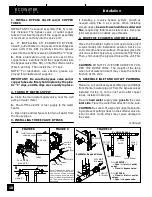

3. INSTALLING THREE VALVE BYPASS

If installing a 3--valve bypass system, plumb as

needed using FIG. 3 as a guide. When installing

sweat copper,

be sure to use lead--free solder and

flux

, required by federal and state codes. Use pipe

joint compound on outside pipe threads.

4. MOVE THE ECOWATER UNIT INTO PLACE

Move the EcoWater System Unit (resin tank only if

2--tank model) into installation position. Set it on a

solid, smooth and level surface. If needed, place the

unit on a section of plywood, a minimum of 3/4”thick.

Then, shim under the plywood to level the unit, FIG.

7.

CAUTION:

DO NOT PLACE SHIMS DIRECTLY UN-

DER THE BRINE TANK.

The weight of the tank,

when full of water and salt, may cause the tank to

fracture at the shim.

5. ASSEMBLE INLET AND OUTLET PLUMBING

Measure, cut, and loosely assemble pipe and fittings

from the main water pipe (or from the bypass valves

installed in step 3), to the inlet and outlet copper

tubes, installed in step 1b.

Be sure

hard water

supply pipe

goes to

the valve

inlet side

. Trace the water flow direction to be sure.

CAUTION

: Be sure to fit, align and support all plumb-

ing to prevent putting stress on the softener valve in-

let and outlet. Undo stress may cause damage to

the valve.

continued

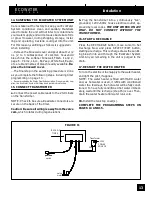

ground wire

clamp (2)

nozzle &

venturi

o--ring

elbow

FIGURE 8

FIGURE 9

FIGURE 10

Note: To ease brine tubing con-

nection, use the elbow and o--

ring seal as shown. Lubricate

the o--ring and insert into the el-

bow. Turn the elbow on and tight-

en. Then, back--off up to 1 turn,

as needed.

B

A

3 -- Valve Bypass

OUTLET

VALVE

INLET

VALVE

BYPASS

VALVE

to conditioner

from conditioner

EcoWater Bypass Valves

SERVICE

BYPASS

D

for

SERVICE:

-- Open

the

inlet

and

outlet

valves.

-- Close

the

bypass valve.

D

for

BYPASS:

-- Close

the

inlet

and

outlet

valves.

-- Open

the

bypass valve.

PUSH

IN

for

bypass

PULL

OUT

for

service

brine tubing

nut--ferrule

screen

Install hose clamps before

soldering copper tubes

copper

tubes

hose clamp,

ground (2)

ground wire