ECOWATER

S Y S T E

M S

Service Information

31

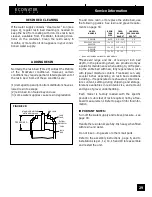

AUTOMATIC ELECTRONIC DIAGNOSTICS

The faceplate computer has a self--diagnostic func-

tion for the electrical system (except input power and

water meter). The computer monitors electronic

components and circuits for correct

operation. If a malfunction occurs, an

error code appears in the faceplate

display.

The chart below shows the error codes that could

appear, and the possible defects for each code.

While an error code appears in the display, all face-

plate buttons are inoperable except the SELECT

button. SELECT remains operational so the service

person can make the MANUAL INI-

TIATED ELECTRONIC DIAGNOS-

TICS, below, to further isolate the de-

fect, and to check the water meter.

POSSIBLE DEFECT

CODE

MOST LIKELY

'

--------------------------------------------------------------------

'

LEAST LIKELY

Error 1 Error 2

Error 3 Error 4

valve defect causing high torque / motor inoperative / wiring harness or connection to

position switch / switch

Error 5

faceplate

PROCEDURE FOR REMOVING ERROR CODE FROM FACEPLATE:

1. Unplug transformer-------- 2. Correct defect--------

3. Plug in transformer-------- 4. Wait for 6 minutes. The error code will return if the defect was not corrected.

TROUBLESHOOTING,

MANUAL INITIATED ELECTRONIC DIAGNOSTICS

1.

To enter diagnostics,

press the SELECT/EXIT

(

¿

) to enter the menu. This

screen contains informa-

tion that can be used to

troubleshoot errors. Use

the (

-

) and (

¯

) buttons to

scroll through all lines on

this screen.

The first line shows time of day and error code.

Second line is

Pos:

which shows what position the

valve is in. Example: Service, Fill, Brining and Brine

Rinse, Backwash and Fast Rinse. The clock to the

right counts backward the time for each of the posi-

tions to be completed.

The next line is

Req Pos:

which is for requested

position, or what position the valve is travelling to.

Next line displays

Motor:

, either on or off, and

Sw:

either open or closed.

Next is

Trbn:

and

Gals:

which indicate water meter

operation as follows.

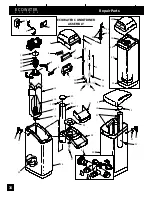

000 (steady) = conditioned water not in use...no flow

through the meter.

--open a nearby CONDITIONED WATER faucet--

000 to 151 (continual) = repeats display for each gal-

lon of water passing through

the meter.

If you don’tget a reading in the display, with a faucet

open, pull the sensor housing from the valve outlet

port. Pass a small magnet back and forth in front of

the sensor. You should get a reading. If you

do get

a reading

, disconnect the outlet plumbing and

check the turbine for binding. If you

don’t get a

reading

, the sensor is probably defective

turbine

mounting

assembly

turbine

sensor housing

BACK OF TIMER

CIRCUIT BOARD

magnet

sensor pickup

continued