B-16

Cautions in making piping connection (Continued)

WARNING

When the piping connection work for the wheel coolant water and spindle

coolant water is completed, check looseness of connections for the joints

If water leakage should occur, the floor surface and downstairs might be damaged.

Lock out the water and air valves before you proceed to installation/

maintenance of the machine

If any air valve or water valve at the plant facility side is opened by other persons

during machine installation or maintenance, it may cause an accident or machine

failure.

CAUTION

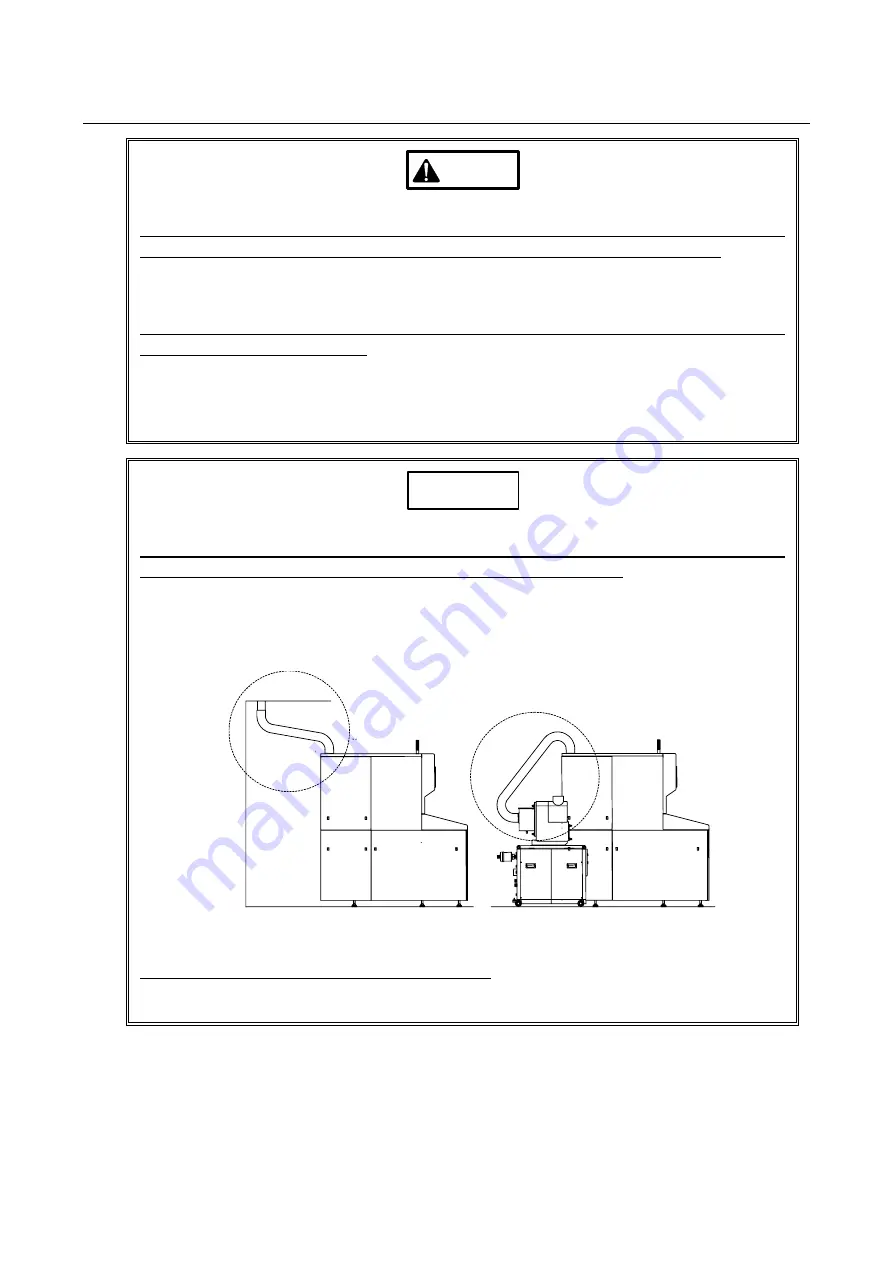

A hose or hard piping line between the machine exhaust duct port and the facility

exhaust system (such as duct unit) must be properly inclined

Also, use props or the like to support the hose as needed. If it is not properly inclined,

water may build up in the duct hose, preventing smooth discharge of exhaust from the

machine. This may cause mist leakage from the grinding chamber and resultant

serious machine failure.

[Good example]

Inclining the hose prevents water buildup in the hose.

Ensure that the air hose is properly installed

If the air hose is disconnected while the spindle is rotating, the spindle may seize up.