CC7574DKV OPERATOR’S MANUAL

Replacing the Rear Wheels

Replace the rear wheels when they are

damaged and/or affecting saw performance.

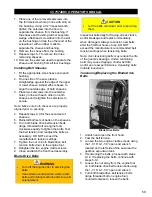

Rear Wheel

1. Move the saw to level ground. Use a jack to

lift the rear wheels off the ground.

2. Pry the hubcap off the wheel using a

screwdriver or pry bar.

3. Remove all four lug nuts from the wheel.

4. Remove the wheel and place a new wheel

onto the wheel hub.

5. Replace the lug nuts and tighten to secure.

6. Replace the hubcap and secure in place

using a rubber mallet.

7. Replace the second rear wheel as directed.

Slowly lower the jack and remove the jack

stand when the wheels are firmly touching

the ground.

Maximum Cutting Depth

WARNING

•

Raise the saw to a proper height for

access when working underneath the

saw. Use chocks to block the wheels,

and fit blocks or jacks under the frame

edges at the front and back of the frame.

Always adjust the maximum cutting depth

when changing the blade size, sheave size,

flange size, and belt size to avoid damaging

saw components. Refer to the CC7574DKV

Parts List for additional information.

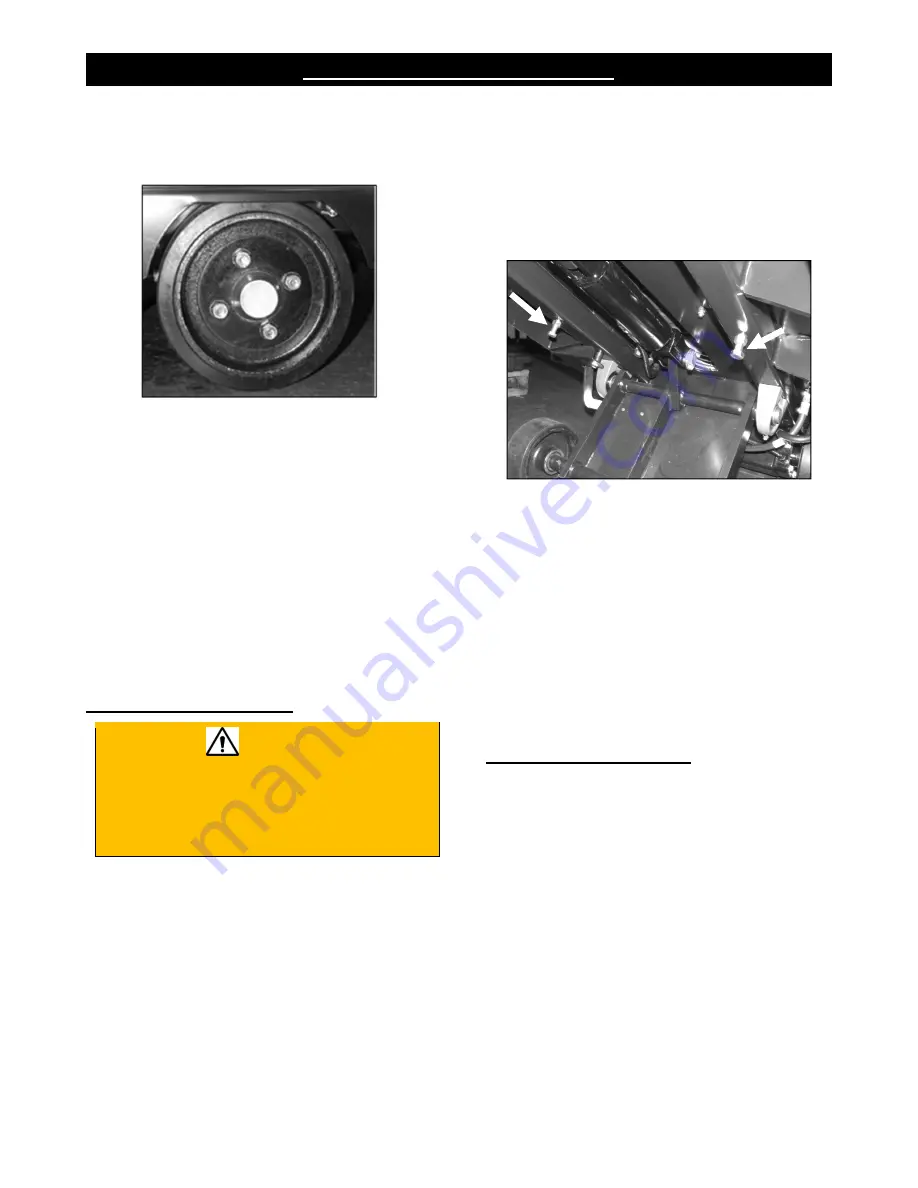

1. Raise the saw to gain access to the

maximum cutting depth bolts underneath

the frame base.

2. Loosen the nut on both bolts.

3. Turn the bolts counterclockwise to

decrease the maximum cutting depth, or

turn the bolts clockwise to increase the

maximum cutting depth.

Note: Both bolts must be the same length

when finished.

Maximum Depth Bolts

4. Bottom out the nut on each bolt with the

frame base to secure the bolts.

5. Remove all tools from the area and lower

the saw completely. The blade flanges

must be at least 1/4” from the ground to

prevent component damage.

Note: Make sure both skid plates on the front

of the saw are in the correct set of holes to

lower the saw completely (refer to

CC7574DKV Parts List).

6. Readjust the depth bolts as necessary.

Handlebar Cylinder Rod

The handlebar cylinder rod must be serviced

by Diamond Products if the handlebars can be

moved up or down in excess amounts when

locked in place (movement may feel sluggish).

Send the entire assembly to Diamond

Products to be recharged or pressurized.

56

Содержание CC7574DKV

Страница 1: ...CORE CUT OPERATOR S MANUAL CC7574DKV CC7574DKV 3 MAY 2022 Part 1802742 01...

Страница 2: ......

Страница 11: ...CC7574DKV OPERATOR S MANUAL CC7574DKV Specifications 11...

Страница 12: ...CC7574DKV OPERATOR S MANUAL CC7574DKV 3 Specifications 12...

Страница 65: ...CC7574DKV OPERATOR S MANUAL Appendix B CC7574DKV RPM Chart CC7574DKV 3 RPM Charts 65...

Страница 66: ...CC7574DKV OPERATOR S MANUAL 66...

Страница 67: ...CC7574DKV OPERATOR S MANUAL CC7574DKV Blade Size Conversion Chart 67...

Страница 68: ...CC7574DKV OPERATOR S MANUAL CC7574DKV 3 Blade Size Conversion Chart 68...

Страница 71: ......