CC7574DKV OPERATOR’S MANUAL

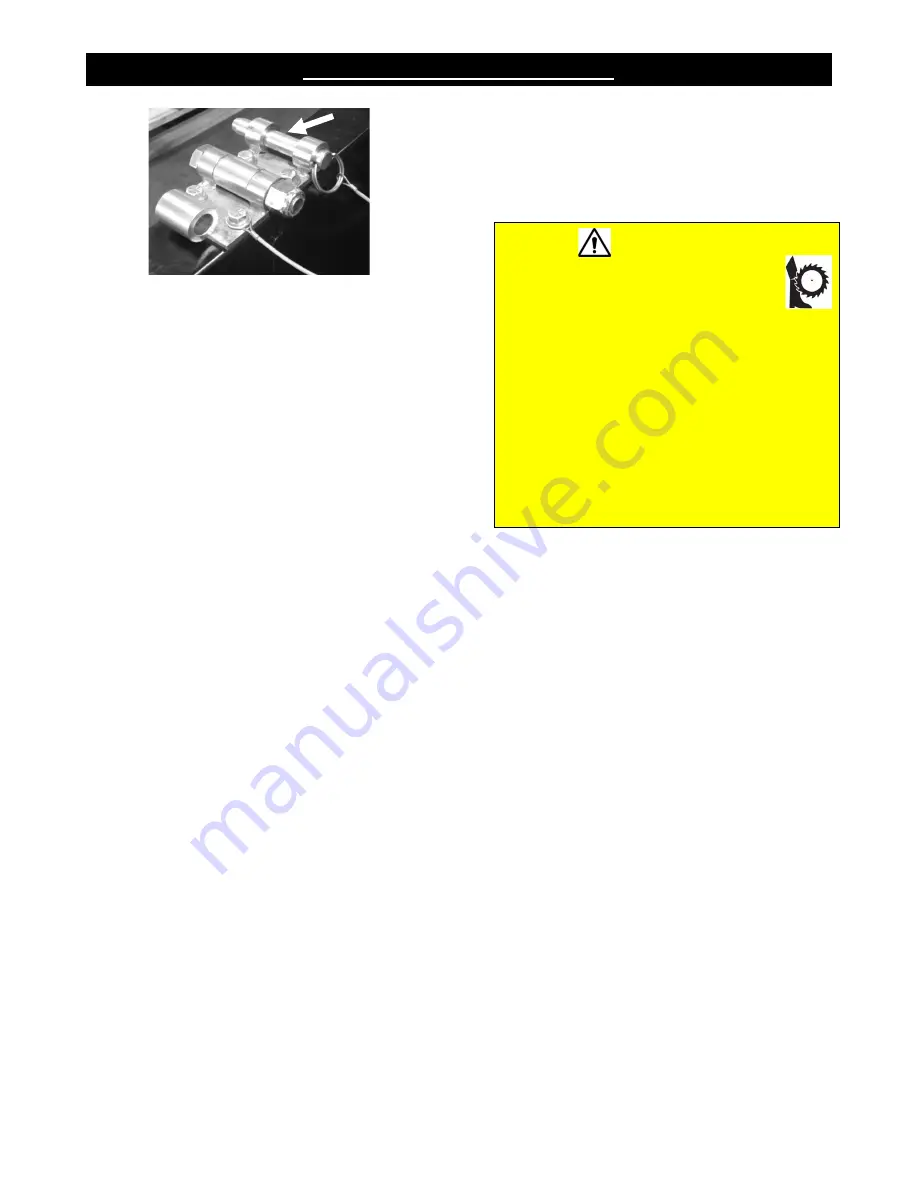

Detent Pin

3. On the pivoted guards, insert the detent pin

through the interlocking barrels on the top

of the guard to secure the front of the

guard.

Note: Failure to fully pivot and secure the front

of the guard may cause serious injuries.

4. Remove the blade shaft bolt. Note:

clockwise loosens on right side,

counterclockwise loosens on left side

(when viewed from the operating position)

using the provided wrench located on the

right side of the control panel.

5. Carefully remove the outer flange. Inspect

the flange assembly and clean or replace

dirty/damaged components.

6. Place the blade against the inner flange.

For large blades, carefully roll the blade up

to the inner flange. Adjust the height of the

saw to align the flange and blade arbor.

Note: Point the arrow printed on the blade in

the direction of the blade shaft’s rotation.

7. Align and fit the outer flange and flange pin

through the blade and into the inner flange

and blade shaft.

Note: The outer flange should fit snug with the

blade, inner flange, and blade shaft.

8. Slightly rotate the outer flange and blade

backward to eliminate backlash

(looseness) between parts.

9. Place the wedge lock washer onto the

blade shaft screw and insert the screw into

the blade shaft through the center of the

outer flange.

10. Tighten the screw by hand. Slowly lower

the saw, if necessary, until the blade just

touches the ground.

11. Tighten the screw again, using the wrench,

to 125 ft-lb (170 Nm) minimum to secure

the outer flange and blade.

12. Remove the detent pin (guards 26” and up)

from the guard hinge and pivot the front of

the guard down over the blade to secure.

13. Re-insert the detent pin.

Removing the Blade

CAUTION

•

DO NOT remove a blade with

the engine running.

•

DO NOT pivot the front of the blade

guard up or down when removing very

large blades. Attempting to pivot the

front of a heavy guard when the guard is

positioned higher up for blade removal

makes the guard difficult to lift and/or

lower. In this situation, remove the blade

guard front instead of pivoting it.

•

Always secure the pivoted section of the

blade guard using the detent pin (guards

26” and up).

1. Remove the detent pin (guards 26” and up)

from the guard hinge and pivot the front of

the blade guard 180° (fully upward) to gain

access to the blade. For larger, heavier

guards that are positioned too high up and

are unsafe to pivot, remove the lock nut

and screw from the center of the guard

hinge. Remove the front of the guard.

Note: Have a second trained operator hold the

guard in place while removing the hinge screw

and nut.

2. On the pivoted guards, insert the detent pin

through the interlocking barrels on the top

of the guard to secure the front of the

guard.

Note: Failure to fully pivot and secure the front

of the guard may cause serious injuries.

3. Slowly lower the saw, if necessary, until the

blade just touches the ground.

4. Remove the blade shaft screw using the

wrench located on the right side of the

control panel.

5. Carefully remove the outer flange and

blade. Place the blade in an appropriate

storage location.

Note: If the outer flange is difficult to remove,

tighten a setscrew into two of the holes on the

outer flange to help separate the outer flange

from the blade.

34

Содержание CC7574DKV

Страница 1: ...CORE CUT OPERATOR S MANUAL CC7574DKV CC7574DKV 3 MAY 2022 Part 1802742 01...

Страница 2: ......

Страница 11: ...CC7574DKV OPERATOR S MANUAL CC7574DKV Specifications 11...

Страница 12: ...CC7574DKV OPERATOR S MANUAL CC7574DKV 3 Specifications 12...

Страница 65: ...CC7574DKV OPERATOR S MANUAL Appendix B CC7574DKV RPM Chart CC7574DKV 3 RPM Charts 65...

Страница 66: ...CC7574DKV OPERATOR S MANUAL 66...

Страница 67: ...CC7574DKV OPERATOR S MANUAL CC7574DKV Blade Size Conversion Chart 67...

Страница 68: ...CC7574DKV OPERATOR S MANUAL CC7574DKV 3 Blade Size Conversion Chart 68...

Страница 71: ......