01/2018

71 / 80

6159933780

Issue no: 09

CVIL II

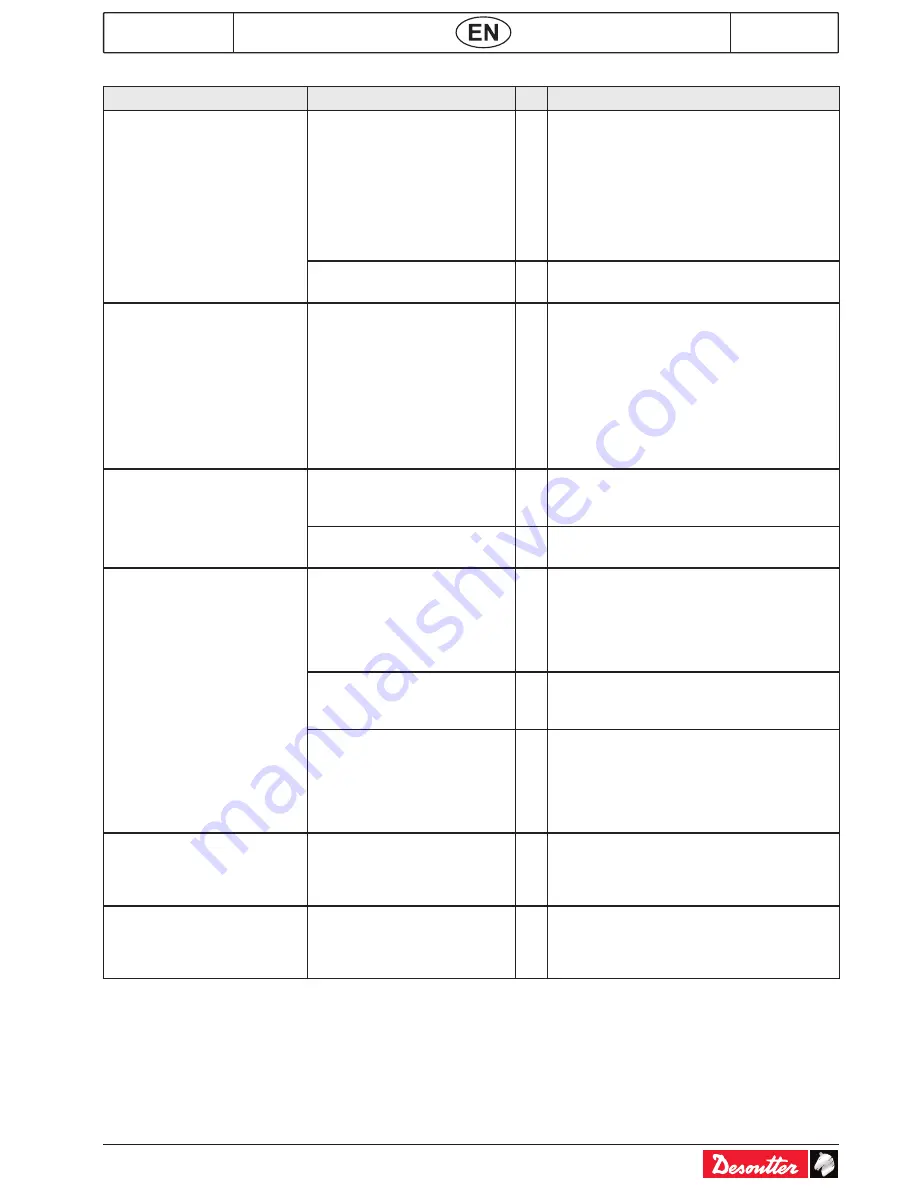

13.3 - Operating problems due to adjustment problems

Symptoms

Possible causes

N° Check

The tool starts then stops

immediately without running

the rundown speed cycle.

The "stall torque" instruction is

too low.

The programmed current is too

low.

The acceleration time is

too short compared to the

maximum time.

The maximum time is too short

or null.

01

Check the values programmed for the run

down and final speed sequences.

A machine part impedes the

rotation of the tool.

02

Please contact your local Customer Center.

The tool skips the rundown

sequence.

The "current" instruction is too

low.

The acceleration time is too

short.

The rundown instruction is too

low.

The maximum rundown time is

too short.

The spindle is not validated in

the sequence.

03

Check the values programmed for the run

down sequence.

Seen from the controller side,

the tool does not reach the

programmed torque or hardly

reaches it.

The power programmed during

the relevant phase is not

sufficient.

04

Check and increase the programmed value if

necessary.

The tool is not suited to the

task.

05

Check that the tool performances are

compatible with the required torque.

Dispersion or abnormal

deviation in the tightening

results.

The rundown torque is too high

as compared to the final torque.

06

Check the torque rise curves.

Reduce the speed of the tool in case of hard

joints.

Check the value of the rundown torque: The

recommended value is close to a quarter of

the final torque.

The deceleration between the

rundown phase and the final

phase is too slow.

07

Reduce the transition interval between the

rundown and tightening phases.

The tightening speed is too

high; the consequence of inertia

is the significant overstepping

of the set value.

08

Reduce the speed of the tightening phase.

The technology of electric motors equipped

with a "resolver" allows the speed reduction

up to 1 % of the maximum speed of the tool.

In most case, a rotation of 20rpm will be the

best compromise.

The torque displayed by the

controller is far from the actual

torque.

The coefficient of the tool

nominal load has been updated

by mistake.

09

This coefficient should be equal to 1, except

in the case of additional reduction gears.

Check its value in the "Parameter/Tool"

menu.

The torque value is constantly

equal to 0; there is no error

message.

The coefficient of the tool

nominal load has been set to 0

by mistake.

10

This coefficient should be equal to 1, except

in the case of additional reduction gears.

Check its value in the "Parameter/Tool"

menu.

Содержание CVIL II

Страница 2: ......

Страница 12: ...01 2018 12 80 6159933780 Issue no 09 CVIL II 4 2 2 Language selection 4 2 3 Setting the date and time...

Страница 77: ...01 2018 77 80 6159933780 Issue no 09 CVIL II...

Страница 78: ...01 2018 78 80 6159933780 Issue no 09 CVIL II...

Страница 79: ...01 2018 79 80 6159933780 Issue no 09 CVIL II...

Страница 80: ...www desouttertools com More Than Productivity Copyright 2016...