01/2018

67 / 80

6159933780

Issue no: 09

CVIL II

13 - TROUBLE SHOOTING HELP

13.1 - Warning

Choose one of these 2 methods to look for information in

this document:

● Locate the error message(s) displayed on the

screen of the controller among the messages listed

in the document. A detailed explanation helps you

understand the message(s). Cross-references

leading to the error causes are suggested whenever

this is possible.

● Select the relevant symptom among those listed.

Each possible cause is numbered to make the search

easier when cross-references are used.

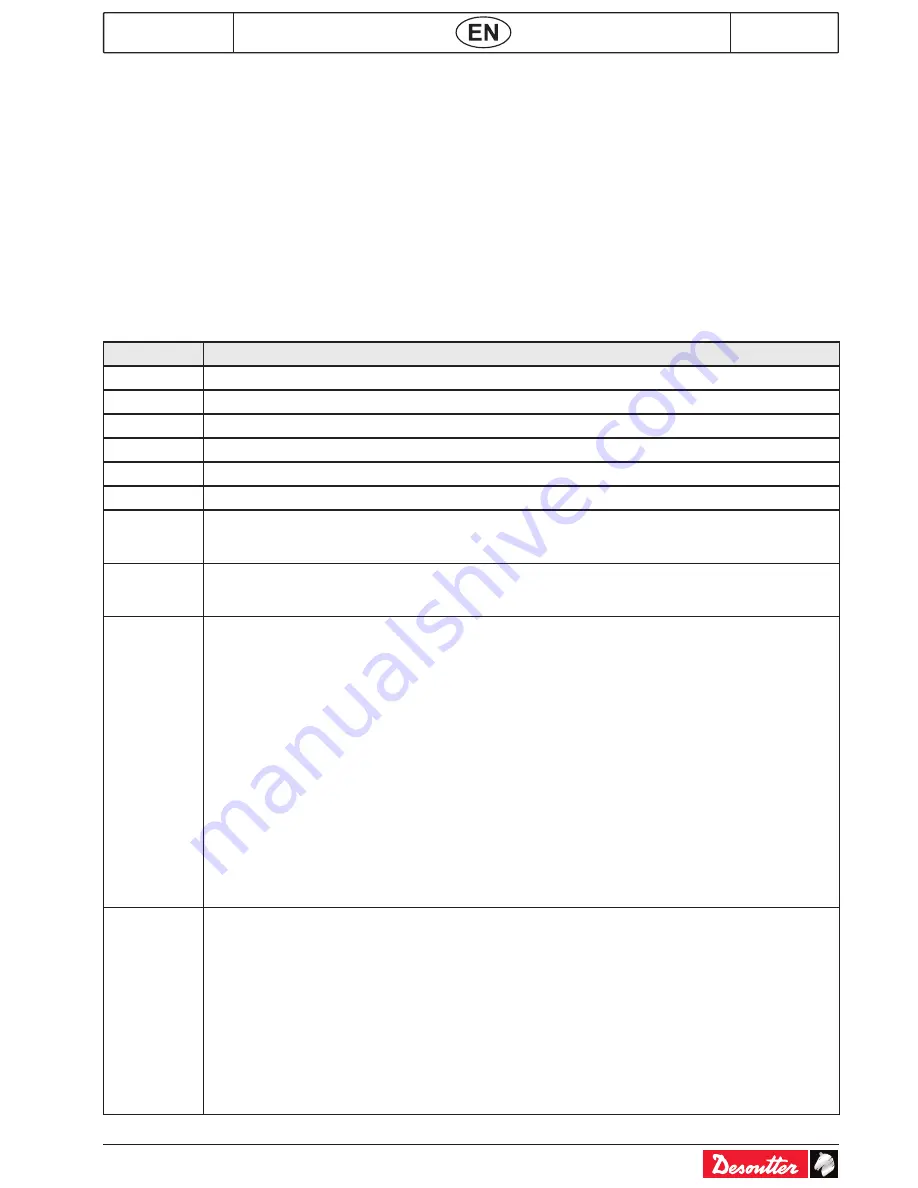

13.2 - Report codes

Text

Comments

Accept

Accept report

Reject

Reject report

Tmin

The final torque at the end of the cycle is lower than minimum torque tolerance.

Tmax

The final torque at the end of the cycle is higher than the maximum torque tolerance.

Amin

The final angle at the end of the cycle is lower than the minimum angle tolerance.

Amax

The final angle at the end of the cycle is higher than maximum angle tolerance.

Scy

Cycle was aborted because the trigger switch was released prematurely.

If it happens only just before reaching the target torque, torque and angle results may be within the

programmed tolerances.

Time

Cycle was stopped after the time allocated for this phase or this cycle is elapsed and not by the

target parameter.

The programmed time out has to be modified to fit the application.

Err

EITHER the tool or the programmed cycles are not consistent with the station mode.

You can try the following:

● Make sure the station mode is set correctly, according to the tool.

● Go back to the cycle parameters and save it again, so that the station mode used for the cycle is

the current running one.

OR the speed is not constant when the torque is reached.

Torque measurement is cancelled during speed transitions.

This message mainly appears in case of hard joints. You can try the following adjustments:

● Reduce the final speed to increase the phase time (remain > 3%).

● Reduce final speed phase acceleration time to minimum (0.01 s) to reach the tightening speed as

quickly as possible.

● Reduce the run down speed phase to avoid high over torque when clamping and to limit the

speed gap between the run down and final speed phase.

If the Err message remains, it means that the joint is too hard to change the speed after clamping.

Try to program a new strategy: Angle run down + Final speed phase.

As the run down phase must end before clamping, the speed transition between the 2 phases no

longer needs to be rapid (0.3 s is sufficient).

NOT READY

List of errors preventing the controller from being ready:

● Over-current: Maximum servo drive current is reached.

● Differential: Earth ground connection opened (the controller does not check earth linkage). This

error is often due to a cable problem.

● Thermal contact: Maximum motor temperature is reached (100°C). This error remains activated

until the motor temperature falls below 80°C.

● SPI link error: The cycle was aborted due to a digital communication problem (SPI) between the

controller and the tool.

● FLEX version error

● Maximum current (Imax)

● Resolver: Position change or non zero speed detected when the motor start is not activated.

● Temperature: Power components over temperature.

Содержание CVIL II

Страница 2: ......

Страница 12: ...01 2018 12 80 6159933780 Issue no 09 CVIL II 4 2 2 Language selection 4 2 3 Setting the date and time...

Страница 77: ...01 2018 77 80 6159933780 Issue no 09 CVIL II...

Страница 78: ...01 2018 78 80 6159933780 Issue no 09 CVIL II...

Страница 79: ...01 2018 79 80 6159933780 Issue no 09 CVIL II...

Страница 80: ...www desouttertools com More Than Productivity Copyright 2016...