PS-28 Cruiser

PS-28N Cruiser

CR-MM-1-0-00

CHAPTER 15 – AIRPLANE REPAIRS

Revision No.: -

Date of issue: 2011-03-08

15 - 16

15.6.2.3

Application of primer (paint)

In order to reach a uniform resistance to corrosion and smooth surface, we recommend

carry out application by means of spraying (air standard gun with the upper vessel, air HVLP

gun, airless electric gun). The adjusting of the used gun (given by manufacturer) differs

according to the type - air pressure, jet diameter. Primer should be applied in several

sprayings (total thickness is not reached at a blow) with defined maximum dwell and total

drying time till further treatment or handling. Primer serves especially for anchoring

(adhesion to the substrate) the topcoats and can serve also for eliminating irregularities of

the surface (function of filer, for sanding). For surfaces from Al-alloys we recommend to use

the etch-primers for light metals based on alkyd or materials based on epoxy or

polyurethane (2-component paints); specific recommendations according to the table 15-6.

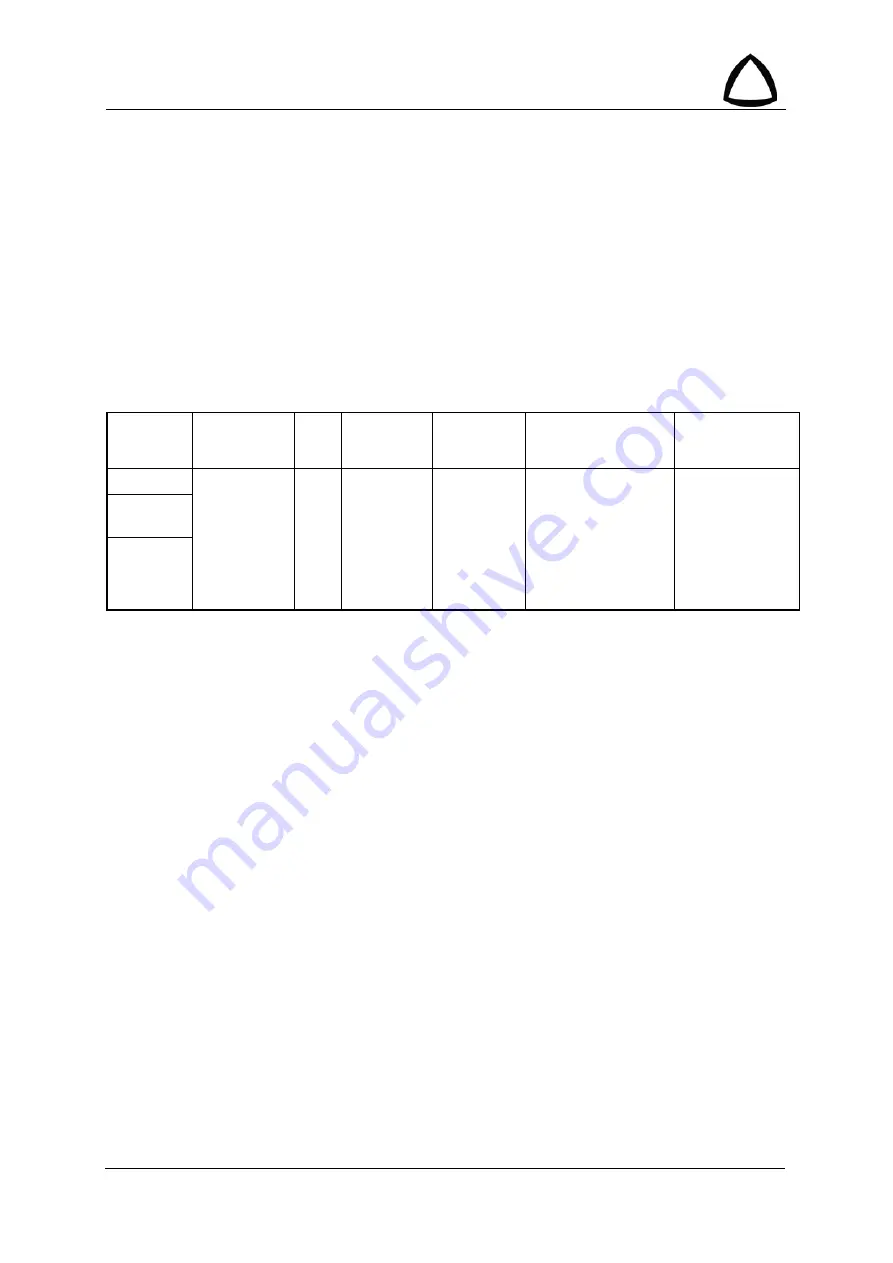

Surface

Manufacturer,

name

Type

Further

components

Surface

mass

Recomm. thickness

Drying (between

spraying / total)

18°C (65°F)

Al-alloys

BASF

Glasurit

801-1880

(base)

epoxy

BASF

Glasurit

965-35/2

(hardener)

Glasurit

965-50

(thinner)

1.6

[kg/mm/m

2

]

8.49

[

lb/in/sq.ft

]

0.025 mm (

0.00098”

)

(at 0.05 mm (

0.00197”

)

it can be also used as

filler)

15 min / 12 FH

epoxy –

fiberglass

PC (Lexan),

PMMA

(Plexiglass)

Tab. 15-5

: Recommended primers

15.6.2.4

Bonding

After total drying of basic coat we recommend to carry out total bonding of irregularities

including repairs of bonding. Recommended binders are shown in the table 15-5. After

drying perform sanding with emery paper with grain size of 240 until the surface is smooth.

After sanding clean dust and wipe of with grease remover and perform repairing paint coat

by primer (1/3 of coat thickness).

15.6.2.5

Application of top coat

In order to reach smooth surface we recommend again carry out the paint coat by spraying

(see 15.6.2.3).

Topcoat serves especially for creating the coat resistant to weather and external effects for

aesthetic rendering of the unit. Considering the higher loading by external effects we

recommend to use top materials, exclusively two-component ones, on the acrylic-

polyurethane or polyurethane basis, always with guaranteed adhesiveness to the used base

coat (according to manufacturer). It is possible to use to advantage some of the coat system

for car repairing. In our recommendation (see Tab. 15-7)

there are two types of colors: single coat (color shade and protection in one) double coat

(one-component color shade is formed by the substrate and protection is ensured by two-

component transparent top coat). By single coat paint it is possible to reach the wide

spectrum of colors, but it is difficult to do metallic paint coats (we do not recommend them).

Содержание CRUISER AIRCRAFT PS-28 Cruiser 2021

Страница 2: ...CR MM 1 0 00 Revision No 25 Date of issue 2021 01 15 ii INTENTIONALLY LEFT BLANK ...

Страница 4: ...CR MM 1 0 00 Revision No 25 Date of issue 2021 01 15 iv INTENTIONALLY LEFT BLANK ...

Страница 356: ...PS 28 Cruiser PS 28N Cruiser CR MM 1 0 00 CHAPTER 17 APPENDICES Revision No 4 Date of issue 2012 12 10 17 6 ...

Страница 357: ...CR MM 1 0 00 PS 28 Cruiser PS 28N Cruiser CHAPTER 17 APPENDICES Date of issue 2012 12 10 Revision No 4 17 7 ...

Страница 358: ...PS 28 Cruiser PS 28N Cruiser CR MM 1 0 00 CHAPTER 17 APPENDICES Revision No 4 Date of issue 2012 12 10 17 8 ...