10

F.

Move boiler to permanent location

by sliding or

walking. Do not drop.

G.

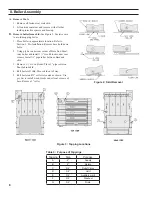

Confirm that one (1) Flue Baffle is properly

positioned in each Boiler Flueway.

Tabs at the top

of each Flue Baffle should be resting on top row of Flue

Pins on each adjoining section.

H.

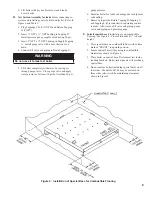

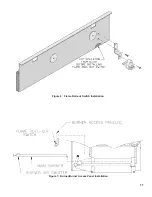

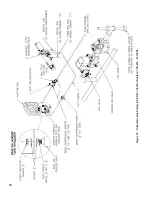

Install Canopy

on section assembly. See Figure 5.

Canopy and hardware are located in Combination

Boiler Parts and Control Carton.

1. Position Canopy on top of Section Assembly. Locate

between end sections and sealing ledge on front and

back of each section.

2. Fasten each end with ¼” - 20 x 1” carriage bolts,

washers and nuts.

3. Seal between Canopy and Section Assembly with

furnace cement.

I.

Inspect joints between sections.

They were factory

sealed. If any openings resulted during shipment or

handling, reseal with furnace cement. Confirm tie rods

are only hand tight to allow for thermal expansion.

J.

Install Base Front Panel.

See Figure 5. Panel and

hardware located in Combination Boiler Parts and

Control Carton.

1. Attach Base Front Panel to Section Assembly using

¼” - 20 x 1¼” carriage bolts, washers and nuts.

2. Seal between top of Base Front Panel and Section

Assembly with furnace cement (shipped in

Combination Boiler Parts and Control Carton).

3. Seal between top of Base Rear Panel and Section

Assembly with furnace cement.

K.

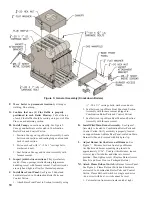

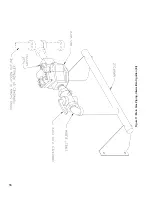

Install Pilot/Main Burner Assembly.

See Figure 7.

Assembly is located in Combination Boiler Parts and

Control Carton. Verify assembly is properly located

on support bracket in Base Rear Panel, seated on Main

Burner Orifice, and secured with hitch pin clip.

L.

Adjust Burner Air Shutters on all Burners.

See

Figure 7. Distance between front edge of Burner

Air Shutter and burner mounting ring should be

approximately 11/16”. To adjust this distance, loosen

screw at top of air shutter and slide into correct

position. Then tighten screw. (Replace Burner Access

Panel(s) and Front Door on Packaged Boilers.)

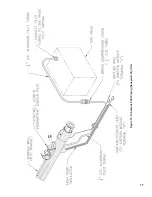

M.

Attach Flame Roll-out Switch

to Burner Access Panel.

See Figure 6. Flame Roll-out Switch and hardware

are located in Combination Boiler Parts and Control

Carton. Flame Roll-out Switch is a single use device

- do not test with heat - switch cannot be reset.

1. Cut insulation from semicircular notch at right

Figure 5: General Assembly (Knockdown Boilers)

Содержание 16H-340

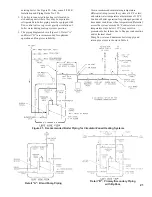

Страница 11: ...11 Figure 6 Flame Roll out Switch Installation Figure 7 Burner Burner Access Panel Installation ...

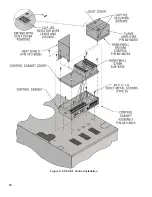

Страница 13: ...13 Figure 8 Jacket Assembly ...

Страница 14: ...14 Figure 9 EP CSD 1 Control Installation ...

Страница 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

Страница 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Страница 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

Страница 31: ...31 Figure 31 Wiring Diagram Honeywell EI USA Intermittent Circulation 16H 340 16H 510 MegaStor Relay MegaStor ...

Страница 37: ...37 Figure 41 Operating Instructions EI ...

Страница 47: ...47 Honeywell EI Trouble Shooting Guide ...

Страница 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 58: ...58 ...

Страница 60: ...60 ...