25

A.

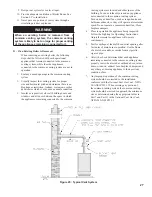

Install vent system

in accordance with local building

codes; or local authority having jurisdiction; or

National Fuel Gas Code

, ANSI Z223.1/NFPA 54, Part

7, Venting of Equipment. Install any of the following

for this Series 16H Category I, draft hood equipped

appliance:

1. Type B or Type L gas vent. Install in accordance

with listing and manufacturer’s instructions.

2. Masonry or metal chimney. Build and install in

accordance with local building codes; or local

authority having jurisdiction; or

Standard for

Chimneys, Fireplaces, Vents, and Solid Fuel

Burning Appliances.

Masonry chimney must be lined with approved

clay flue lining or listed chimney lining system

except as provided in ANSI Z223.1/NFPA 54,

Paragraph 7.5.4(a):

Exception: Where permitted by

the authority having jurisdiction, existing chimneys

shall be permitted to have their use continued when

an appliance is replaced by an appliance of similar

type, input rating, and efficiency

.

3. Single wall metal vent. Allowed by ANSI Z223.1/

NFPA 54 under very restrictive conditions.

B.

Inspect chimney

and remove any obstructions or

restrictions. Clean chimney if previously used for solid

or liquid fuel-burning appliances or fireplaces.

DANGER

Inspect existing chimney before installing boiler.

Failure to clean or replace perforated pipe or tile

lining will cause severe injury or death.

C.

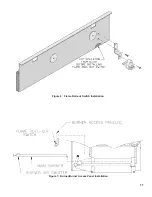

Install Draft Hood

on canopy outlet. Maintain height

from Jacket Top Panel to Draft Hood skirt as shown

in Figure 1. DO NOT ALTER, CUT, OR MODIFY

DRAFT HOOD.

WARNING

Do not alter boiler draft hood or place any

obstruction or non-approved damper in the

breeching or vent system. Flue gas spillage can

occur. Unsafe boiler operation will occur.

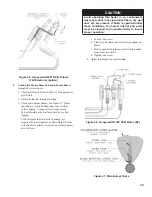

D.

Install Blocked Vent Switch.

The Blocked Vent

Switch Assembly consists of a strain relief bushing,

power cord, and switch attached to mounting bracket.

The assembly is located in Combination Boiler Parts

and Control Carton.

1. Uncoil power cord.

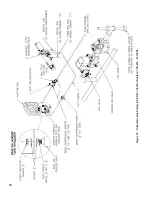

2. Position mounting bracket onto lower edge of Draft

Hood skirt. Locate center tooth (with #10 sheet

metal screw) on outside and other two teeth inside

Draft Hood skirt. See Figure 23.

3. Slide mounting bracket tight against lower edge of

Draft Hood skirt. Position #10 sheet metal screw

above skirt’s stiffening rib.

4. Secure bracket in position by tightening #10 sheet

metal screw against outer surface of Draft Hood

skirt.

5. Insert excess power cord through Jacket Right Side

Panel hole. Remove slack.

6. Position strain relief bushing around power cord.

Pinch bushing’s two halves together and snap back

into hole in Jacket Right Side Panel.

7. Verify power cord, mounting bracket, and Blocked

Vent Switch are secure and located as shown in

Figure 23.

WARNING

Do not operate boiler without Blocked Vent Switch

Properly installed.

VI. Venting

Figure 23: Blocked Vent Switch Installation

Содержание 16H-340

Страница 11: ...11 Figure 6 Flame Roll out Switch Installation Figure 7 Burner Burner Access Panel Installation ...

Страница 13: ...13 Figure 8 Jacket Assembly ...

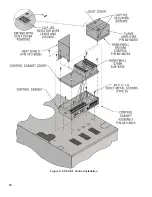

Страница 14: ...14 Figure 9 EP CSD 1 Control Installation ...

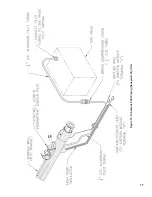

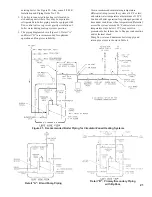

Страница 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

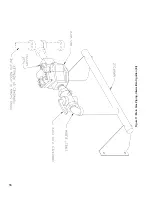

Страница 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Страница 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

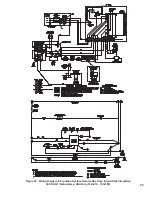

Страница 31: ...31 Figure 31 Wiring Diagram Honeywell EI USA Intermittent Circulation 16H 340 16H 510 MegaStor Relay MegaStor ...

Страница 37: ...37 Figure 41 Operating Instructions EI ...

Страница 47: ...47 Honeywell EI Trouble Shooting Guide ...

Страница 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 58: ...58 ...

Страница 60: ...60 ...