6

I. Pre-Installation

WARNING

Carefully read all instructions before installing

boiler. Failure to follow all instructions in proper

order can cause personal injury or death.

A

.

Inspect shipment

carefully for any signs of damage.

All equipment is carefully manufactured, inspected

and packed. Our responsibility ceases upon delivery

of boiler to carrier in good condition. Any claim

for damage or shortage in shipment must be filed

immediately against carrier by consignee. No claims

for variances or shortages will be allowed by Boiler

Manufacturer, unless presented within sixty (60) days

after receipt of equipment.

B.

Installation must conform

to the requirements of

the authority having jurisdiction. In the absence of

such requirements, installation must conform to the

National Fuel Gas Code

, NFPA 54/ANSI Z223.1.

Where required by the authority having jurisdiction, the

installation must conform to the

Standard for Controls

and Safety Devices for Automatically Fired Boilers

,

ANSI/ASME No CSD-1.

C.

Provide clearance between combustible material

and

boiler jacket (following clearances are minimums):

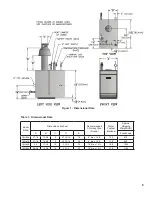

1. 16H-340: listed for Alcove installation

a. Front: 18”

b. Top: 36”

c. Draft hood, rear, sides and flue connector: 6”

WARNING

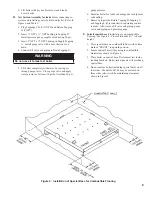

Appliance is design certified for installation on

noncombustible flooring only. For installation

on combustible flooring only when installed on

special base listed in Table 2. Boiler must not be

installed on carpeting. When boiler is installed on

concrete which is over a material that is subject

to melting (PVC, PEX radiant tubing, etc.), the

special base must be used. A concrete pad is not

sufficient to protect combustible flooring.

2. 16H-410-16H-505: for installation in room which is

large in comparison with size of boiler.

a. Front: 18”

b. Top: 51½”

c. Draft hood, rear, sides, and flue connector: 6”

D.

Provide clearance for servicing

and proper operation

(following clearances are recommended and may be

reduced to minimum clearances shown above):

1. Single boiler, 16H-340, Front: 24” (61.0 cm)

2. Single boiler, 16H-410-16H-505, Front: 48”

(122.0 cm)

3. Multiple/modular boiler, Sides: 1” (2.5 cm)

E.

Install boiler on level floor

as close to chimney as

possible. For basement installation provide a solid base

such as concrete or masonry construction if floor is not

level or if water may be encountered on floor around

boiler.

F.

Protect gas ignition system components

from

water (dripping, spraying, rain, etc.) during boiler

operation and service (circulator replacement, control

replacement, etc.).

G.

Provide combustion and ventilation air

in accordance

with applicable provisions of local building codes, or

the

National Fuel Gas Code

, NFPA 54/ANSI Z223.1,

Air for Combustion and Ventilation.

WARNING

Adequate combustion and ventilation air must be

provided to assure proper combustion.

The following guideline is based on the

National Fuel

Gas Code

, NFPA 54/ANSI Z223.1.

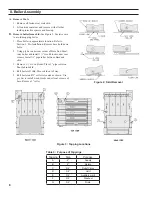

1. Determine volume of space (boiler room). Rooms

communicating directly with space (through

permanent openings not furnished with doors) are

considered part of space.

Volume [ft

3

] = Length [ft] x Width [ft] x Height [ft]

2. Determine Total Input of all appliances in space.

Round result to nearest 1,000 Btu per hour (Btuh).

3. Determine type of space. Divide Volume by Total

Input.

a. If result is greater than or equal to 50 ft

3

per

1,000 Btuh, space is considered an

unconfined

space

.

b. If result is less than 50 ft

3

per 1,000 Btuh, space

is considered a

confined space

.

4. Determine building type. A building of

unusually

tight construction

has the following characteristics:

a. Walls and ceiling exposed to outside atmosphere

have a continuous water vapor retarder with a

Boiler Model

Special Base Part Number

16H-340

61816075

16H-410

61816085

16H-460

61816095

16H-505

61816105

Table 2: Special Base Required for Installation on

Combustible Flooring

Содержание 16H-340

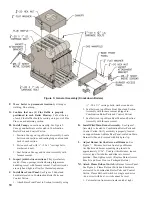

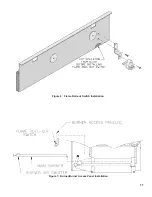

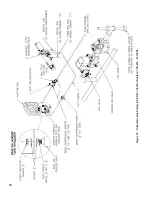

Страница 11: ...11 Figure 6 Flame Roll out Switch Installation Figure 7 Burner Burner Access Panel Installation ...

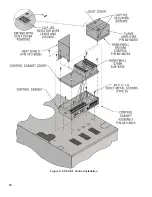

Страница 13: ...13 Figure 8 Jacket Assembly ...

Страница 14: ...14 Figure 9 EP CSD 1 Control Installation ...

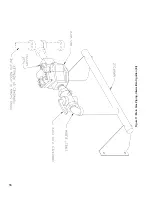

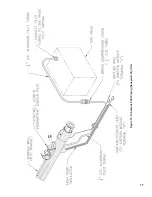

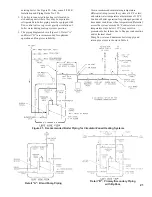

Страница 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

Страница 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Страница 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

Страница 31: ...31 Figure 31 Wiring Diagram Honeywell EI USA Intermittent Circulation 16H 340 16H 510 MegaStor Relay MegaStor ...

Страница 37: ...37 Figure 41 Operating Instructions EI ...

Страница 47: ...47 Honeywell EI Trouble Shooting Guide ...

Страница 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 58: ...58 ...

Страница 60: ...60 ...