21

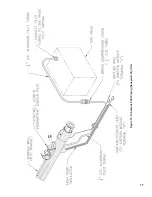

entering boiler. See Figure 20. Also, consult I=B=R

Installation and Piping Guide No. 250.

2. If boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

flow control valves to prevent gravity circulation of

boiler water during cooling system operation.

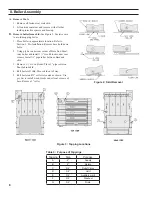

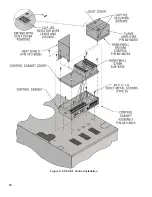

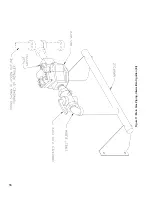

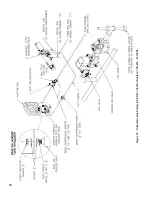

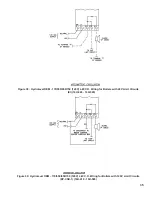

3. The piping diagrams shown (Figure 21, Detail “A”

and Detail “B”) are recommended for optimum

operation and long term reliability.

Crown recommends maintaining temperature

differential (drop) across the system at 40°F or less,

and return water temperature at minimum of 135°F.

Continued boiler operation for prolonged periods of

time under conditions when temperature differential

across the system exceeds 40°F and/or return water

temperature stays below 135°F, may result in

premature boiler failure due to flue gas condensation

and/or thermal shock.

Pump flow rates and minimum boiler supply and

return pipe sizes are shown in Table 4.

Figure 21: Recommended Boiler Piping for Circulator Zoned Heating Systems

Detail “A”: Blend Pump Piping

Detail “B”: Primary/Secondary Piping

with By-Pass

Содержание 16H-340

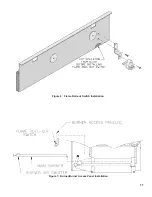

Страница 11: ...11 Figure 6 Flame Roll out Switch Installation Figure 7 Burner Burner Access Panel Installation ...

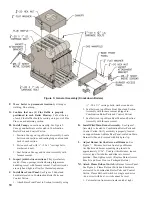

Страница 13: ...13 Figure 8 Jacket Assembly ...

Страница 14: ...14 Figure 9 EP CSD 1 Control Installation ...

Страница 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

Страница 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Страница 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

Страница 31: ...31 Figure 31 Wiring Diagram Honeywell EI USA Intermittent Circulation 16H 340 16H 510 MegaStor Relay MegaStor ...

Страница 37: ...37 Figure 41 Operating Instructions EI ...

Страница 47: ...47 Honeywell EI Trouble Shooting Guide ...

Страница 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 58: ...58 ...

Страница 60: ...60 ...