41

opens to 1.4 or 2.5 inch w.c. and steps to full

pressure after approximately 30 seconds. Check

manifold pressure after step has occurred. Adjust gas

valve pressure regulator as necessary for 10.0 inches

w.c. (turn adjustment screw counterclockwise to

decrease manifold pressure, or clockwise to increase

manifold pressure). If 10.0 inches w.c. can not be

attained, check gas valve inlet pressure. If less than

11.0 inches w.c., contact gas supplier for assistance.

O.

Clean Heating System

Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly flushed. A qualified water treatment

chemical specialist should be consulted for

recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

P.

Check Damper Operation

- If boiler is equipped with

vent damper, vent damper must be in open position

when boiler main burners are operating. Start boiler,

refer to instructions on damper to determine if damper

is in full open position.

Q.

Install Front Removable Panel.

1. Engage top flange (longer of 2 flanges) behind

Upper Front Panel.

2. Swing lower portion of door toward boiler.

3. Lower door to engage bottom flange behind Lower

Front Tie Bar.

R.

Combustion Chamber Burn-Off

1. The mineral wool combustion chamber panels

contain a cornstarch based binder that must be

burned out at installation to prevent odors during

subsequent boiler operation.

2. Ventilate the boiler room, set the high limit to its

maximum setting, set the thermostat to call for heat.

3. Allow the boiler to fire for at least an hour or until

the odor from the cornstarch has dissipated.

4. Return the high limit and thermostat to their desired

settings.

S.

Review User’s Information Manual

and system

operation with owner or operator.

Содержание 16H-340

Страница 11: ...11 Figure 6 Flame Roll out Switch Installation Figure 7 Burner Burner Access Panel Installation ...

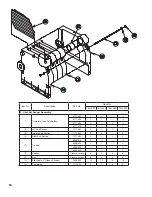

Страница 13: ...13 Figure 8 Jacket Assembly ...

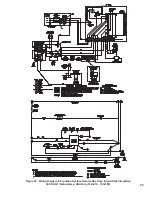

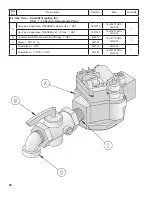

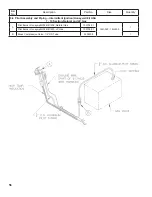

Страница 14: ...14 Figure 9 EP CSD 1 Control Installation ...

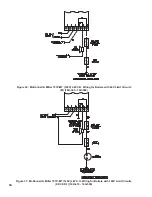

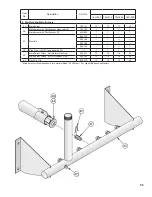

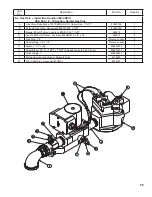

Страница 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

Страница 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Страница 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

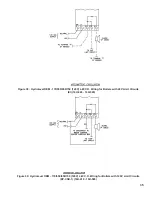

Страница 31: ...31 Figure 31 Wiring Diagram Honeywell EI USA Intermittent Circulation 16H 340 16H 510 MegaStor Relay MegaStor ...

Страница 37: ...37 Figure 41 Operating Instructions EI ...

Страница 47: ...47 Honeywell EI Trouble Shooting Guide ...

Страница 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 58: ...58 ...

Страница 60: ...60 ...