CompAir UK Ltd.

5280D Compressor Publication 98407.1440

Page 12

1440.doc

6.

MAINTENANCE & REPAIR (Cont.)

•

Make sure all instructions concerning operation

and maintenance are strictly followed and that the

complete unit, with all accessories and safety

devices, is kept in good order.

•

The accuracy of pressure gauges and

temperature switches should be regularly

checked at least 13 month intervals and

thoroughly examined at least every 48 months.

They must be renewed or service exchanged

when acceptable tolerances are exceeded.

•

Protection devices should be tested at each

regular service interval and replaced or service

exchanged if not functioning correctly. The

maximum pressure for safety valves under fault

conditions is 1.10 times the set pressure, the set

pressure being a minimum of 1.05 times the

maximum operating pressure to ensure seat

tightness.

•

Never use a light source with an open flame for

inspection.

•

Before dismantling any part of the compressor be

sure that all heavy movable parts are secure.

•

After completion of any maintenance or repair

ensure that no tools, loose items or rags are left

on or inside the compressor.

•

Do not use any flammable liquid to clean valves,

filter elements, cooler passages, pipe bores or

any component carrying a flow of air or gas

during normal operation. If chlorinated

hydrocarbon substances are used for cleaning,

safety precautions must be taken against toxic

vapours which may be released.

DO NOT USE CARBON TETRACHLORIDE.

•

Precautions must be taken against using acids,

alkalis and chemical detergents for cleaning

machined parts. These materials cause irritation

and are corrosive to the skin, eyes, nose and

throat. Avoid splashes and wear suitable

protective clothing and safety glasses. Do not

breathe mists. Ensure water and soap is readily

available.

•

When disposing of condensate, old oil, used filter

elements and other parts and waste material of

any kind make sure that there is no pollution to

any drain or natural water course and that no

burning of waste takes place which could cause

pollution of the atmosphere.

•

Keep the compressor clean at all times. Protect

components and exposed openings by covering

with a clean cloth or tape during repair or

maintenance work.

•

Protect the motor, intake, electrical and regulation

components against the entry of moisture, e.g.

steam cleaning.

•

Precautions must be taken when carrying out

welding or any repair operation which generates

flames or sparks. The adjacent components must

be screened with non flammable material and if

oil present, the system must first be cleansed

thoroughly by steam cleaning.

•

Condensate (oil and water mixture from

compression process) must be regarded as trade

effluent and is therefore not suitable for discharge

into a surface water sewer, soakaway or water

course.

•

PTFE waste disposal.

PTFE products can give fumes if heated above

the temperature of 400 °C, giving rise to “polymer

fume fever.” This flu like condition, the symptoms

of which do not normally occur until several hours

after exposure is temporary, the symptoms

passing off typically within 36-48 hours.

Any scrap or waste material must always be

disposed of by dumping in a landfill site rather

than by incineration. To ensure this, it is

essential to keep the PTFE waste in separate

containers, and not to mix it with other rubbish.

When handling PTFE based rings or packings, or

dust from these components, clean working

practices, including the use of washing facilities

must be encouraged to avoid the transfer of

PTFE particles from hands or clothing to

cigarettes or tobacco.

PROTECT THE ENVIRONMENT USE

APPROVED

METHODS OF DISPOSAL.

7.

PRECAUTIONS IN THE EVENT OF FIRE

•

Use extreme caution when handling components

that have been subjected to fire or very high

temperature. Some components may contain

fluoroelastomer materials which decompose

under these conditions to form highly corrosive

residues. Skin contact can cause painful and

penetrating burns resulting in permanent skin and

tissue damage.

This is a high pressure Compressor

use only :

GENUINE

CompAir UK Ltd

PARTS

Содержание 5280D.1.IAC

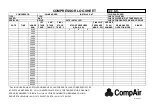

Страница 3: ...DATE REMARKS DATE REMARKS logsheet5280 d...

Страница 9: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 6 1440 doc...

Страница 29: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 26 1440 doc...

Страница 33: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 30 1440 doc...

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 36 1440 doc...

Страница 44: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 38 1440 doc CRANKCASE 1...

Страница 46: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 40 1440 doc CRANKCASE 2...

Страница 48: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 42 1440 doc CRANKCASE 3...

Страница 50: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 44 1440 doc CYLINDER 1st STAGE...

Страница 52: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 46 1440 doc SUCTION VALVE COVER...

Страница 54: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 48 1440 doc DELIVERY VALVE COVER 1st STAGE...

Страница 58: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 52 1440 doc CRANKSHAFT CONNECTING ROD...

Страница 60: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 54 1440 doc CROSSHEAD 1st STAGE...

Страница 62: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 56 1440 doc PISTON 1st STAGE...

Страница 64: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 58 1440 doc GLAND 1st STAGE...

Страница 66: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 60 1440 doc OIL PUMP...

Страница 68: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 62 1440 doc OIL PUMP FILTER...

Страница 70: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 64 1440 doc INTERCOOLER...

Страница 72: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 66 1440 doc 1st STAGE PIPE WORK...

Страница 74: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 68 1440 doc...

Страница 76: ......

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 70 1440 doc...

Страница 87: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 71 1440 doc Appendix 4 Service Plan...

Страница 94: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 72 1440 doc...

Страница 98: ...App 408 Customer PET controller installation guide user s manual Page 2 App 408C 98155 1015...

Страница 120: ...CompAir UK Ltd APP 004 ANTI VIBRATION MOUNTS Page 2 app004 doc...

Страница 122: ...CompAir UK Ltd PUBLICATION APP070 PRESSURE GAUGES GENERAL Page 2 app070 doc...

Страница 128: ...CompAir UK Ltd PUBLICATION APP 138 3 WAY SOLENOID VALVES PS2197 Page 2 app138 doc...

Страница 130: ...CompAir UK PUBLICATION APP034 ELECTRIC MOTOR MAINTENANCE GENERAL Page 2 APP034 doc...

Страница 133: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 74 1440 doc...