INST No. INE-403-0P0

−

6

−

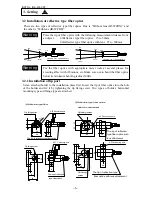

Purge air

inlet

Purge air flow:50 to 200Nl/min

Purge air pressure:Lower than200kPa

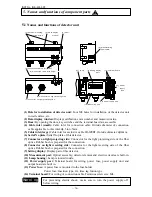

3.2.2 Air purge (Only IR-WCRN)

When air purging is required, supply dry air not

containing oil, dust, etc. from a purge air inlet.

Connect a nylon tube of

φ

6mm in outer diameter and

φ

4mm in inner diameter to the purge air inlet.

(When the reflection type fiber optics is used in

ambient temperature more than 60

°

C, remove the

purge air inlet and pipe to the screw hole of RC1/8

directly.

Purge air flow: 5 to 20NI/min

Purge air pressure: Less than 200kPa (2kgf/cm

2

)

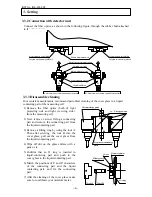

3.2.3 Connections with detector unit

Connect the side being separated into two parts of light projecting side and light receiving

side with the fiber optics connectors of the detector unit.

The fiber optics has “Light projecting side (D)”and “Light receiving side

(E)”and each one has a carved mark. Connect the fiber optics through the

rubber bush as shown in the following figure.

W a rn i n g

3. Setting

!

Connector for fiber

[Light projecting side ]

Connector for fiber

[Light receiving side]

Dent department

Protrusion department

D

E

Rubber bush

Bush fitting ring

Connector ring

Optical fiber

D:Connect to light projecting side

E:Connect to light receiving side