Chapter 2

2-25

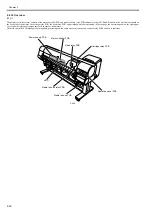

2.3.2.5 Purge Unit

2.3.2.5.1 Functions of Purge Unit

0020-5700

iPF810 / iPF820

To maintain high print quality, the purge unit performs maintenance of the nozzles o the printhead.

The purge unit supports a capping function, cleaning function, and ink supply function.

a) Capping function

The capping function presses the cap of the purge unit against the face plate on the nozzle section of the printhead to prevent nozzle drying and dust adhesion.

Capping is performed when printing is complete, at the start of the suction operation, and when switching to the standby state due to an error.

The capping function also establishes the ink passage between the printhead and purge unit.

b) Cleaning function

The cleaning function restores the printhead to the state where ink can be easily discharged from nozzles. This function includes the following three types of oper-

ations.

- Wiping operation

This operation is performed to remove paper fibers and dried ink from to the face plate.

- Pumping operation

This operation is performed to remove ink from the nozzles and fill the nozzles with fresh ink.

- Maintenance jet operation

This operation is performed to spray ink from the nozzles to the cap, HP maintenance jet tray, BP maintenace jet tray, maintenance jet ink groove of the platen to

remove bubbles in the nozzles and dust and other foreign particles.

c) Ink supply function

The suction pump of the purge unit operates together with the ink supply valve to supply ink to the printhead during the initial filling and ink level adjustment.

Details of the cleaning function are shown in the table below.

T-2-8

Cleaning mode

Name of Service mode

or PRINT INF

(Name of Main Menu)

Operation

Description of cleaning

Cleaning 1

CLN-A-1/CLN-M-1

(Head Cleaning A)

Normal cleaning

Removes dried ink from nozzles, thick ink accumulated on the

face, and paper particles.

Cleaning 2

CLN-A-2

Ink level adjustment and cleaning

Adjust the ink level in the head by suction, and then performs

normal cleaning.

Cleaning 3

CLN-A-3

Initial filling ink

Fills the empty tube (during initial installation) with ink, and

then performs normal cleaning.

Cleaning 4

CLN-M-4

(Replace P.head)

Ink drainage for head replacement

Drains ink to replace the head (drains only the ink in the head).

Cleaning 5

CLN-M-5

(Move Printer)

Ink drainage for secondary transport

Drains ink from the head and tube for secondary transport.

Cleaning 6

CLN-A-6/CLN-M-6

(Head Cleaning B)

Normal (strong) cleaning

Performs suction stronger than when adjusting the ink filling

amount in the head or normal cleaning to unclog nozzles.

Cleaning 7

CLN-A-7

Aging

Performs idle ejection after replacement of the head.

Cleaning 10

CLN-A-10

(Move Printer)

Ink filling after secondary transport

Fills the empty tube (during installation after secondary

transport) with ink, and performs normal cleaning.

Cleaning 11

CLN-A-11

Ink filling after head replacement

Performs normal cleaning after head replacement and ink

filling.

Cleaning 15

CLN-A-15

Dot count suction

Performs suction to remove ink adhered to dried nozzles and

thick ink accumulated on the face when the dot count reaches

the prescribed value.

Cleaning 16

CLN-A-16

Precipitated ink agitation

Performs the agitation (ink supply valve open/close) operation

to prevent the ink ingredient from precipitating.

Cleaning 17

CLN-A-17

Cleaning (weak)

Performs cleaning weaker than normal cleaning to unclog

nozzles.

Содержание iPF800 Series

Страница 1: ...Aug 13 2008 Service Manual iPF800 series ...

Страница 2: ......

Страница 6: ......

Страница 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Страница 12: ......

Страница 14: ......

Страница 38: ...Chapter 1 1 24 Hold this lever to pull out the lower roll unit ...

Страница 90: ...Chapter 1 1 76 3 Push in the left and right Basket Rods toward the back all the way until they stop F 1 41 ...

Страница 100: ...Chapter 1 1 86 ...

Страница 101: ...Chapter 2 TECHNICAL REFERENCE ...

Страница 102: ......

Страница 147: ...Chapter 2 2 43 This function relays the image data from the main controller PCB to the printhead ...

Страница 158: ......

Страница 159: ...Chapter 3 INSTALLATION ...

Страница 160: ......

Страница 162: ......

Страница 176: ...Chapter 3 3 14 ...

Страница 177: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Страница 178: ......

Страница 180: ......

Страница 227: ...Chapter 4 4 47 Media type Gloss photo paper 2 Paper gap adjustment Service mode SERVICE MODE ADJUST GAP CALIB ...

Страница 238: ...Chapter 4 4 58 ...

Страница 239: ...Chapter 5 MAINTENANCE ...

Страница 240: ......

Страница 242: ......

Страница 246: ...Chapter 5 5 4 5 Close upper cover 1 F 5 6 1 ...

Страница 247: ...Chapter 5 5 5 ...

Страница 248: ......

Страница 249: ...Chapter 6 TROUBLESHOOTING ...

Страница 250: ......

Страница 252: ......

Страница 274: ......

Страница 275: ...Chapter 7 SERVICE MODE ...

Страница 276: ......

Страница 278: ......

Страница 301: ......

Страница 302: ......

Страница 303: ...Chapter 8 ERROR CODE ...

Страница 304: ......

Страница 306: ......

Страница 318: ...Chapter 8 8 12 ...

Страница 319: ...Aug 13 2008 ...

Страница 320: ......